Gold continuous concentrator CC, continuous auto discharge ore

2022-08-01

staurk machinery

Gold continuous concentrator CC for sale

Gold continuous concentrator CC for sale

Gold continuous concentrator CC for sale

What is a gold continuous concentrator (CC) ?

Continuous concentrator ( CC in short ) for continuous discharge mining,

For batch centrifugal gold concentrator, stone ore is generally discharged once every 1-4 hours, and placer is discharged once every 4-12 hours.

In practical applications, if continuous operation is required, a continuous concentrator is required.

In practical applications, if continuous operation is required, a continuous concentrator is required.

Gold continuous concentrator (CC), feeding range: 0-3.2mm, suitable for a wide range of solid concentration of the incoming material, and the concentration of the incoming material can be within 70%. The rate of concentrate mineral can be arbitrarily set at 0-50%.

Application of gold continuous concentrator (CC)

Gold continuous concentrator (CC), widely used in gold, silver, platinum, palladium and other precious metals, as well as black (scheelite) tungsten, cassiterite, tantalite, chromite, ilmenite, rutile, iron oxide minerals and sulfide containing gold and silver things, etc.When use batch and when use continuous?

Concentrate rate < 0.1% with batch concentrator;

Concentrate rate > 0.1% with continuous concentrator.

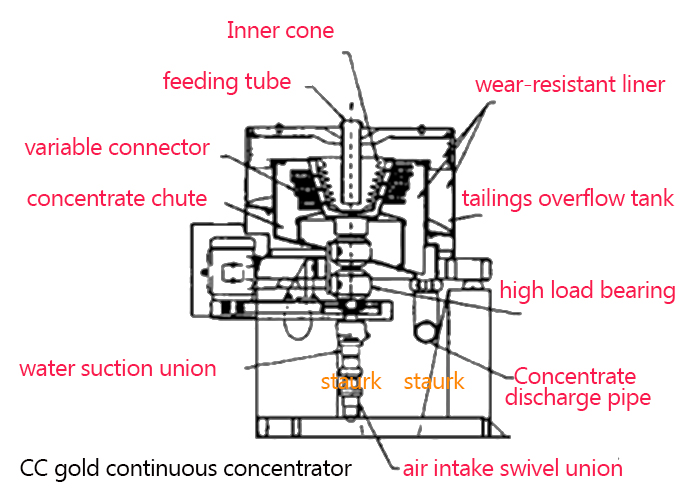

Structure of gold continuous concentrator (CC)

Structure of gold continuous concentrator includes : Inner cone,feeding tube,concentrate chute,water suction union,wear-resistant liner,tailings overflow tank,high load bearing,Concentrate discharge pipe,air intake swivel union etc.

Advantages

1) No pollution, clean, no need to add any chemicals;

2) The beneficiation enrichment ratio is high, usually reaching 1000-3000 times, the concentrate grade is high, generally 1000-20000g/t, and the recovery rate is significantly higher than that of conventional gravity separation equipment;

3) The processing capacity of a single equipment is large, the equipment operation rate is high, and the power consumption is low;

4) Easy to operate and manage, few operators are required, high degree of automation, low daily maintenance of equipment and low production cost

5) The equipment occupies a small area and is easy to integrate into the reconstruction and expansion plants or new plants

6.) The selection process is short, the investment is small, and the return time is short.