Bauxite rotary dryer | Bauxite ore powder clay oven dryer - China

Condition:New

Origin:Henan, China

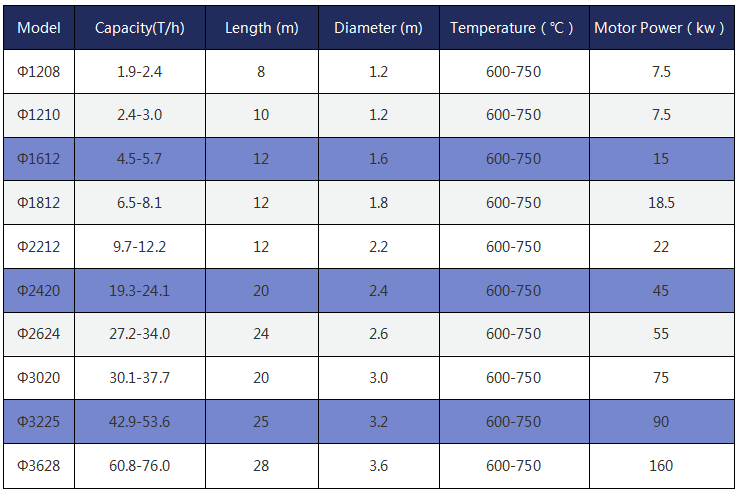

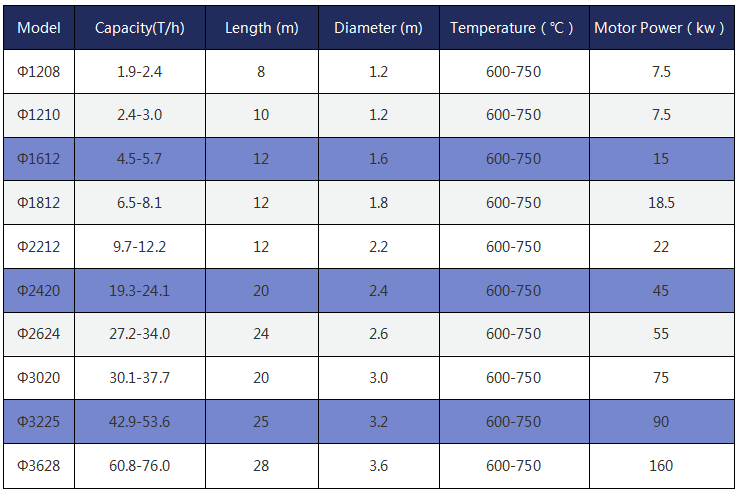

Daily Capacity:40-1520 T/D

Drying Temperature:600- 750℃

Total Installed Power:7.5-160 kw

Final Moisture:12-15% (adjustable)

Used for:Bauxite Ore , Bauxite clay, powder, coal, mining, slime, bauxite, kaolin, bentonite, aluminum slag, metal slag, etc.

Bauxite rotary dryer | Bauxite ore powder clay oven dryer - China

Bauxite dryer manufacturer

Henan Staurk Machinery Co,.Ltd, China. We are the rotary dryer manufacturer, Rotary dryer is mainly composed of heat source, feeding device, belt feeder, rotary drum, belt discharger, induced draft fan, dust collector and power distribution cabinet, etc.It can use a variety of heat sources, has the characteristics of strong adaptability, fast drying speed, small footprint, customizable models, and high cost performance.

Bauxite dryer Application

It can be used for Bauxite Ore , Bauxite clay, powder, coal, mining, slime, bauxite, kaolin, bentonite, aluminum slag, metal slag, etc.

Parameter of the Bauxite dryer

Bauxite introduction :

Bauxite is also called bauxite,and its main mineral components are gibbsite,boehmite and diaspore.The main purpose of bauxite is as a raw material for the production of alumina and metallic aluminum.

Metal aluminum has excellent properties such as small specific gravity,good electrical and thermal conductivity,and easy machining,so its importance is second only to steel.

Although the amount of aluminum used in non-metallic applications is relatively small,it is quite extensive,such as as a raw material for abrasive materials,refractory materials,chemicals,and high-alumina cement.

Bauxite

Bauxite

Bauxite dryer tips :

1.The roller should be turned on first during production,and the material should be put into production after the roller rotates normally.

2.The drying drum is generally 2-6 r/min under normal operation and production,and the surface linear speed of the drum does not exceed 1m/s.

3.The drying drum is made of plain carbon steel,so the high temperature flue gas in the drum should not be higher than 700℃.

During the normal operation of the drum,it is not allowed to stop running,otherwise the drum may be bent and deformed and cause the drum to be scrapped.Therefore,after the production and shutdown,the drum should continue to run for a period of time until the surface temperature of the drum is lower than 150℃.

If there is a sudden power failure,use the hand to drag the reducer pulley to keep the drum running for a certain period of time,and wait for the drum to cool down before stopping.

4.The meshing of the ring gear and the gear should be at the index circle.Due to thermal expansion and contraction,the meshing accuracy of the teeth should be checked frequently,and neither jam nor mesh size should be too small.

5.The matching of the supporting roller and the rolling ring should be fully matched under normal conditions,and the matching size should be more than 2/3 when the expansion and contraction due to high temperature occurs.

Features of Bauxite rotary dryer:

1.The air outlet temperature is low,and the dust removal equipment has a long use time.

2.The use of a new type of combined lifting device can easily adjust the required final moisture index according to user requirements.

3.High degree of automation,convenient operation and stable operation.

4.The investment required for the equipment is 1/6 of the foreign imported products.The investment is small and the return is fast.

5.It adopts the supporting wheel to rotate,and the transmission power is small.

6.Compared with the single-cylinder dryer,the floor space is reduced by about 50%,the civil construction investment is reduced by about 50%,and the power consumption is less than 60%.

7.The fuel can be adapted to coal,oil and gasoline.