Tyre shredding machine for sale, China rubber car tire shredder price

Tyre shredding machine video

Make tyre into fine powder

Because tires have a certain toughness, compared to plastic is also more wear-resistant, so the tire shredder generally uses a higher model of motor and reducer.

The capacity is 0.5- 20.0 tph, discharge size is 2-20cm.

Appliaction of Tyre shredder machine

Shredding various types of used tires (car tires , truck tires, bias tires , radial tires, pneumatic tires , solid tires, ≤800mm small car tires , ≥900mm cart tires) ,

Waste tire recycling and disposal system also includes steel wire separation, iron removal, fiber separation, etc.,

Can help users to obtain higher purity rubber powder, steel wire, fuel oil, combustible gas and carbon black, etc, which is more profitable than directly selling waste tires.

blade of tyre shredding machine

blade of tyre shredding machine

Waste tire / tyre recycling and disposal system

It includes tire shredding, wire separation, iron removal, fiber separation and other disposal equipment, and can also add deep processing equipment such as granulator, rubber breaker, pulverizer, etc., through the intelligent management system to realize the automatic operation of the entire tire recycling and disposal production line.

Why recycling tyre is a good bussiness ?

Also known as the "black gold mine", scrap tires are made up of rubber, steel, carbon black, and various chemicals, and their recycling is a mature and lucrative business. Using waste tires to make tire-derived fuel (TDF), rubber scraps, rubber powder and pyrolysis oil are several representative recycling applications.

Tyre shredder for sale

Tyre shredder for sale

Tyre shredder for sale

Tyre shredder for sale

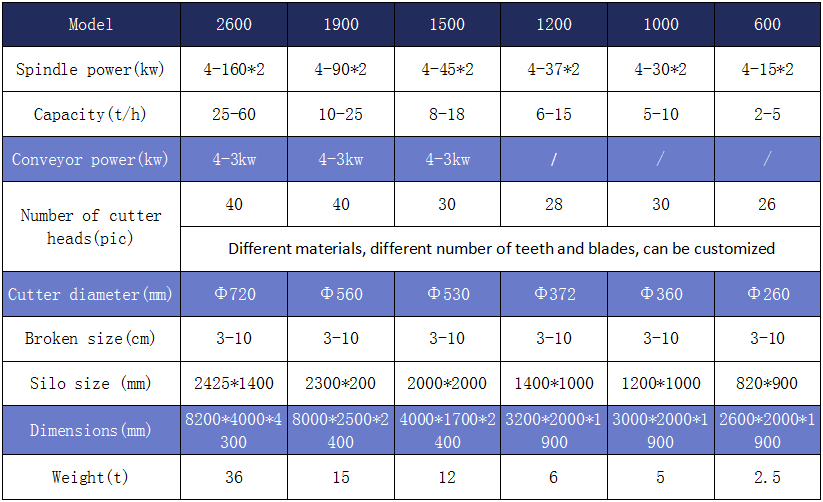

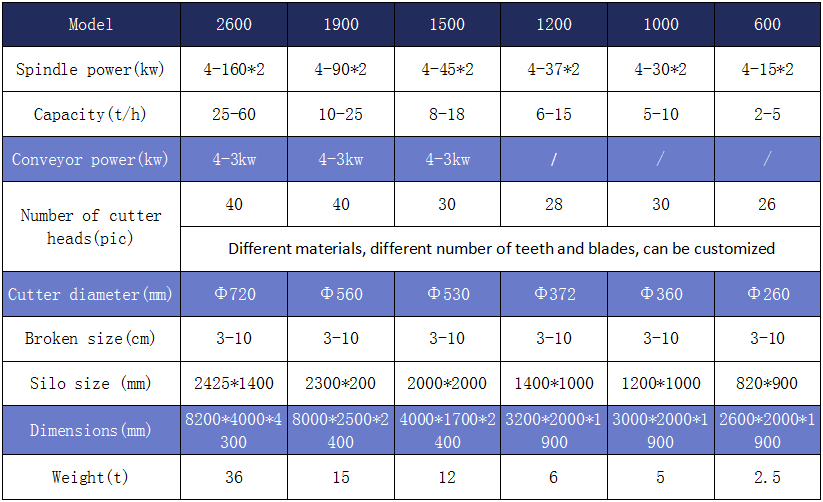

Parameter of the Tyre shredding machine shredder

tyre shredding machine Features:

1.Ultra-low speed, large torque, 5~13 revolutions per minute;

2.low noise, low dust;

3.Optional electric or hydraulic motor;

4.According to the different nature of materials, customers are free to choose integral shredding blades or assembled detachable blades;

5.The optional hydraulic forced feeding device can shred materials more efficiently and quickly;

6.The double locking structure at both ends of the shaft head ensures the installation position of the blade and prevents axial displacement;

7.Adopts microcomputer (PLC) automatic control, with start, stop, reverse and overload automatic reverse control functions;

8.Feeding test 80~100 hours before leaving the factory to ensure the reliability of the equipment.

Current situation of tire in China:

According to statistics, the annual scrap amount of tires in China is no less than 1.5 million tons, increasing by 10% every year, while the current recovery rate is only 30%. As waste rubber can not be comprehensively utilized, most of them become industrial waste, which not only wastes a lot of available resources, but also causes black pollution, seriously affecting human living environment.

China's annual consumption of rubber ranks first in the world. At the same time, China is also a country with serious shortage of rubber resources.

The annual import of rubber accounts for 60% of the total consumption, and there is no fundamental way to get rid of the status quo in a short period of time.