Cardboard paper baling press machine,briquette waste carton| China staurk

Condition:New

Origin:Henan, China

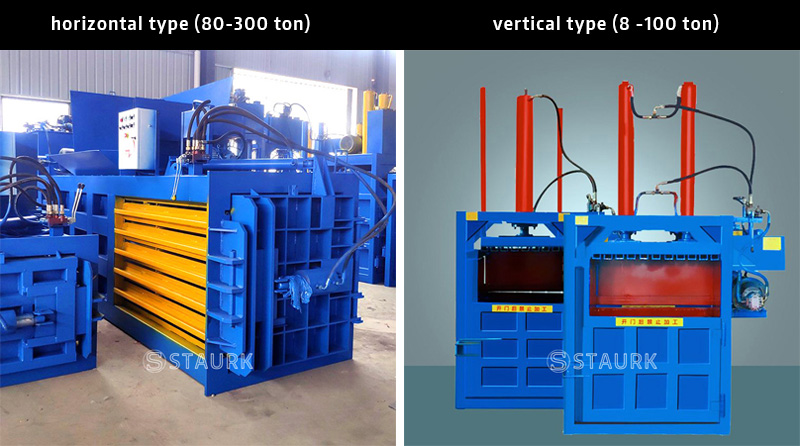

Pressure:8 ton - 100ton, 80 ton - 300 ton

Type:Vertical type and Horizontal type

Used for:Waste paper, cardboard boxes, old newspapers, cans, plastic bottles, metal scraps, scraps, straws, textiles, paint buckets, animal hair, wood chips, etc.

Cardboard paper baling press machine,briquette waste carton| China staurk

Paper baling press machine

Waste paper baler, also called waste paper briquetting machine,old paper baling machine is used to compress and pack all light foam, loose materials and other soft materials such as waste, discarded cardboard, cartons, old newspapers, documents, etc.

When the material is pressed to a specific density, the threading mechanism will automatically thread the material and push the bundle out of the baler.

Paper baler greatly reduces the volume, increases the density, and facilitates transportation and storage.

Application:

It is used to press all kinds of cartons, cardboard, waste newspapers, straw, wheat straw, paper edge, wood pulp and various wastes, soft fibers, as well as clothing, plastics and metals in animal husbandry, printing, textile, paper and other industries. Block packing.

Compression chamber size and block size can be customized according to customer requirements

Classification:

According to the actual use, it is divided into vertical balers and horizontal balers

Parameter of the Paper baling press machine baler

Horizontal baler parameter

|

Horizontal |

Power(kw) |

Pressure |

Oil Cylinder |

Block Dimension(mm) |

Block weight |

Over all Dimension(mm) |

|

80ton |

18.5 |

80 ton |

185 |

1200*1100*850 |

300-400 |

6000*1100*2300 |

|

100ton |

18.5 |

100 ton |

200 |

1200*1100*850 |

400-500 |

6000*1100*2300 |

|

120ton |

22 |

120 ton |

230 |

1400*1100*850 |

600-700 |

6700*1300*2300 |

|

140ton |

22 |

140 ton |

250 |

1400*1100*850 |

700-800 |

6700*1300*2300 |

|

160ton |

37 |

160 ton |

300 |

1800*1100*1250 |

1000-1300 |

9200*1300*3100 |

|

180ton |

37 |

180 ton |

325 |

1800*1100*1250 |

1100-1300 |

9400*1500*3100 |

|

200ton |

45 |

200 ton |

360 |

1800*1100*1250 |

1100-1300 |

9400*1500*4300 |

Vertical baler parameter

|

Vertical |

Power(kw) |

Pressure |

Block Dimension(mm) |

Bar type |

Dimension(mm) |

Block number |

|

8 ton |

4 |

8 ton |

600*400*600 |

single bar |

1250*650*2150 |

4 - 6 blocks per hour |

|

10 ton |

7.5 |

10ton |

800*400*800 |

single bar |

1450*650*2600 |

|

20 ton |

7.5 |

20ton |

800*400*800 |

single bar |

1450*650*2700 |

|

30 ton |

11 |

30ton |

1000*600*800 |

single bar |

1650*850*2750 |

|

30 ton |

11 |

30ton |

1000*600*800 |

double bar |

1650*850*2700 |

|

40 ton |

11 |

40ton |

1000*600*800 |

double bar |

1650*850*2750 |

|

60 ton |

15 |

60ton |

1200*800*1000 |

double bar |

1600*2100*3100 |

|

80 ton |

18.5 |

80ton |

1200*800*1000 |

double bar |

1700*2100*3300 |

|

100 ton |

22 |

100ton |

1200*800*1000 |

double bar |

1700*2100*3900 |

|

120 ton |

22 |

120ton |

1100*700 |

|

1400*2000*4200 |

Structure

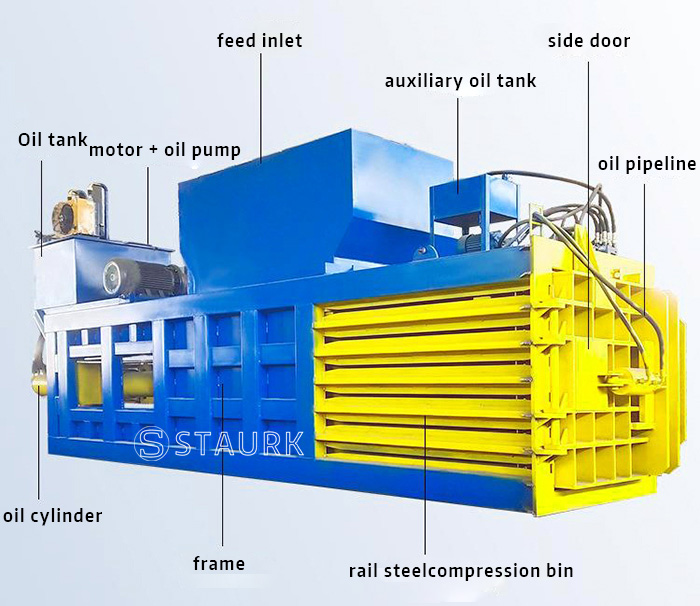

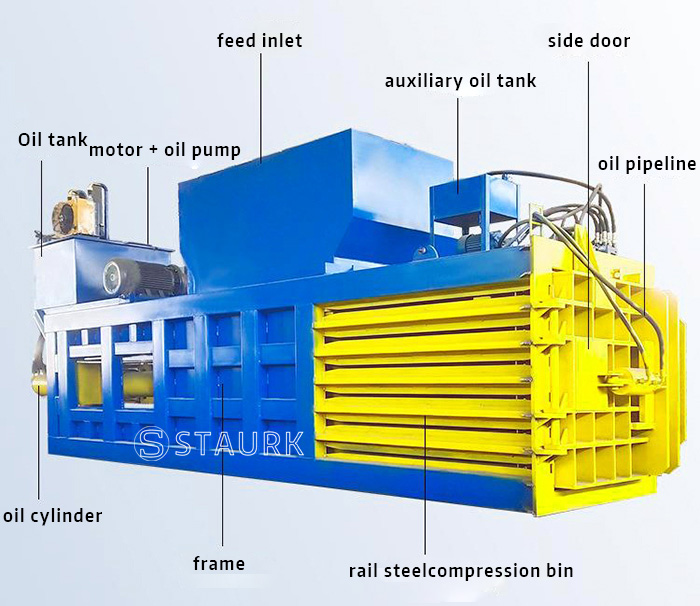

Horizontal paper baler Structure

Horizontal paper baler Structure

Horizontal Paper baling press machine consist of Oil tank, oil cylinder, motor + oil pump, frame, rail steel compression bin, feed inlet, auxiliary oil tank, side door, oil pipeline etc.

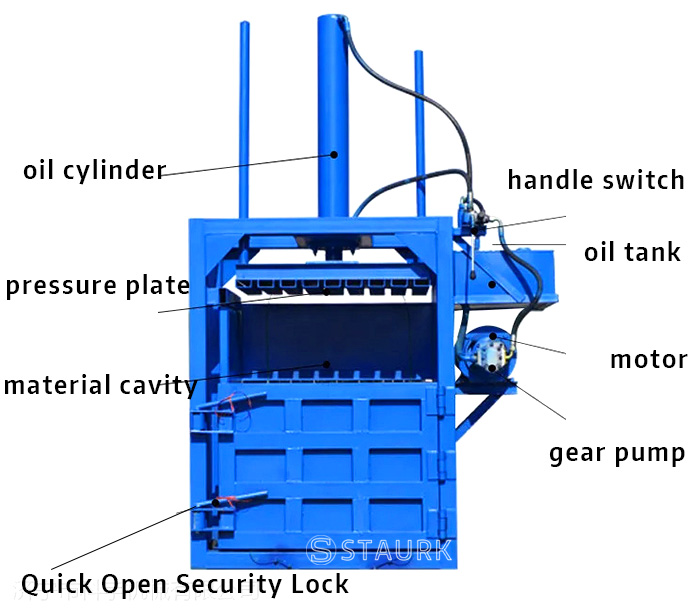

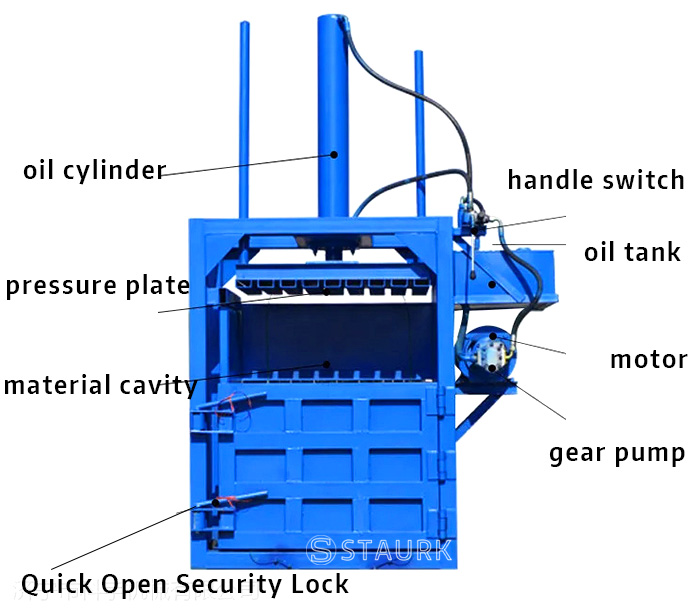

Vertical paper baler Structure

Vertical paper baler Structure

Features

Horizontal Paper baling press machine

The horizontal baler consists of a frame, a hydraulic system, an electric control system, and a feeding system.

1. All models are hydraulically driven.

2. There are different ways of discharging, such as turning the bag, pushing the bag (side push and forward push) or manually picking up the bag (packing).

3. No foot screws are required for installation. In places without power supply, diesel engine can be used as power.

4. There are 20 grades of extrusion force from 10 tons to 300 tons for users to choose.

5. The size of the compression chamber and the size of the block can be customized according to customer requirements.

6. The spherical structure is used between the pushing cylinder and the pushing head, which has good reliability and long service life of the oil seal.

7. The feeding port is widened and enlarged, and the filling is more convenient and fast.

8. Low noise hydraulic circuit design, high efficiency and low failure.

9. Easy to install, no foundation required.

Vertical Paper baling press machine

High pressure cylinder: high temperature resistance. The chrome-plated oil cylinder does not leak pressure, does not leak oil, and is stable and durable

Hydraulic cylinder: high speed, high speed oil delivery, high efficiency

Upgrade the fuselage: The box frame upgrade design, can add more materials and improve work efficiency

Reinforced and heavy pressure plate: the spaced pressure plate is used for three-dimensional pressure bearing, and the packing is strong

Wire tray for storage: convenient for packing after compression, effectively saving space

High-pressure plunger pump: The inlet and outlet parts of the pump are made of cast iron, the pump body is non-corrosive, and the hydraulic oily medium is anti-wear.

Hydraulic power clamping: There is a hydraulic power clamping clamp at each outlet on both sides, which has strong power and can easily adjust the size of the clamping opening according to different materials.