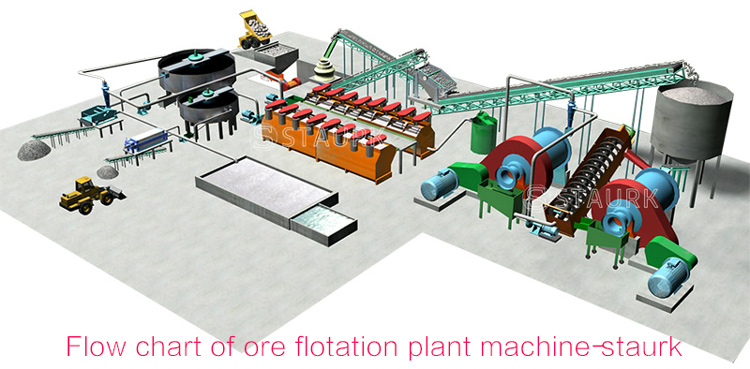

| Equipment | Specification | QTY | Power |

|---|---|---|---|

| Jaw Crusher | PEF 500x750 | 1 | 55 |

| Fine Jaw Crusher | PEX 250x1200 | 2 | 45 |

| Swaying feeder | BK600x600 | 1 | 1.5 |

| Copper ball mill | MQY 2400X3600 | 1 | 280 |

| Spiral classifier | FLG-2000 | 1 | 18.5+3 |

| Agitation tank | XB 2000x2000 | 1 | 5.5 |

| Flotation machine | BF-4 | 24 | 15X24 |

| Belt conveyor | B500 | / | / |

| Equipment | Specification | QTY | Power |

|---|---|---|---|

| Jaw Crusher | PEF 500x750 | 1 | 55 |

| Fine Jaw Crusher | PEX 250x1200 | 2 | 45 |

| Swaying feeder | BK600x600 | 1 | 1.5 |

| Copper ball mill | MQY 2400X3600 | 1 | 280 |

| Spiral classifier | FLG-2000 | 1 | 18.5+3 |

| Agitation tank | XB 2000x2000 | 1 | 5.5 |

| Flotation machine | BF-4 | 24 | 15X24 |

| Belt conveyor | B500 | / | / |