Chrome ore beneficiation processing plant machine chromium chromite concentrate

Chrome ore beneficiation processing plant

Remarks: take as reference

Chrome ore concentrate plant machine

Chrome ore concentrate plant machine

The chorme beneficiation plant mainly includes:

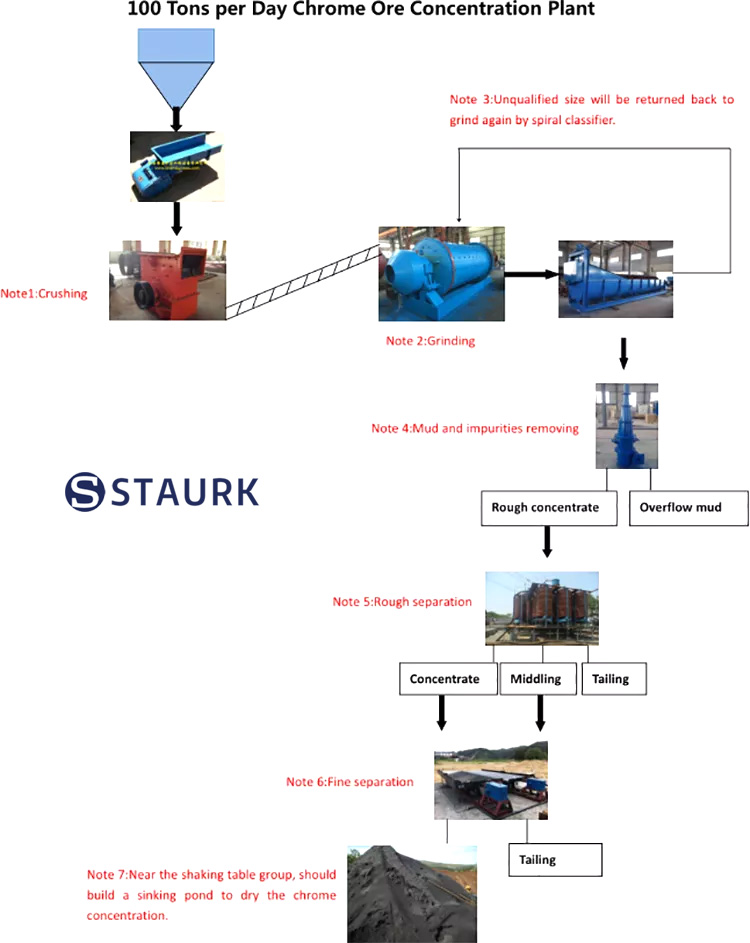

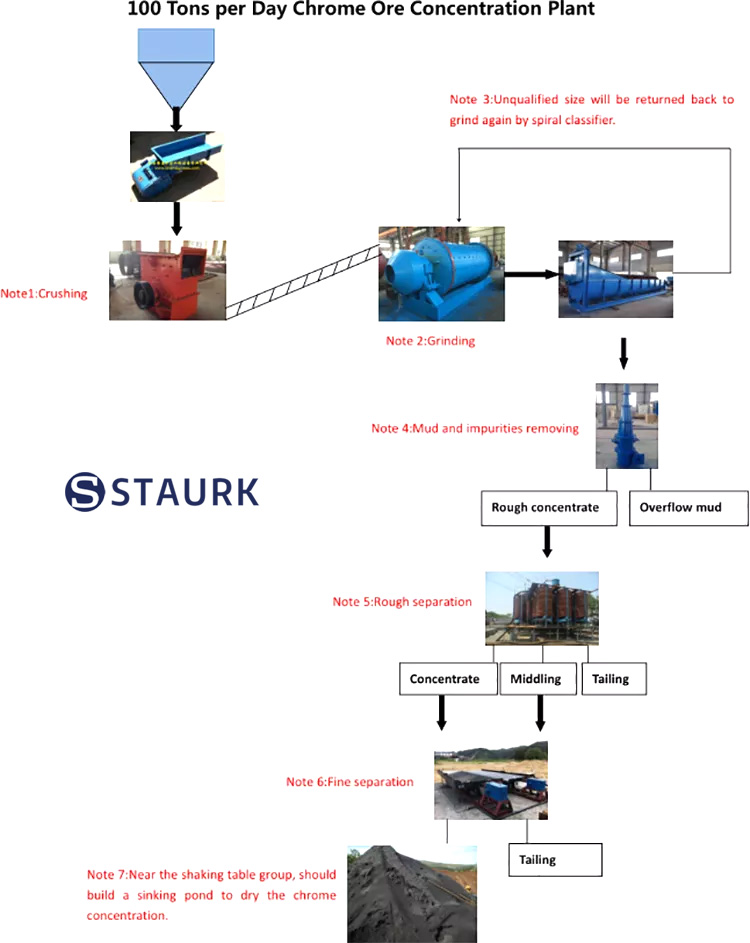

Crusher stage:

Crush chrome raw ore into small pieces, usually by

jaw crusher and fine jaw crusher (sometimes

hammer crusher ), to make sure the ore can feed into next stage.

Usually as small as possiable.

Grinding stage:

Feed crushed chrome ore into

ball mill , to grind ore into fine powder, to control the size , need a

Hydrocyclone

Tailings pricess stage

Due to environmental factors, we need to process tailings by mining thickener , filter etc.

Parameter of the Chrome ore concentrate machine

Chrome ore introduction

Chromium ore is black, in granular structure and massive structure. The ore mineral is mainly chromite, and gangue mineral is olivine, pyroxene, etc. The ore grade is 40%, hardness is 4.5-5, and specific gravity is about f3.5-4.

The content of Cr2O3 in chromium minerals with industrial value is generally more than 30%, and the common ones are:

Chromite

The chemical composition is (Mg, Fe) Cr2O4, which is between ferrochromite (FeCr2O4, containing 32.09% FeO and 67.91 Cr2O3) and magnesia chromite (MgCr2O4, containing 0.96% MgO and 79.04% Cr2O3). Generally, both ferrochromite and magnesia chromite are also called chromite. Chromite is an equiaxed crystal system, with fine octahedron crystals, usually in granular and dense massive aggregates, black color, brown streaks, semi metallic luster, hardness of 5.5, specific gravity of 4.2~4.8, and weak magnetism. Chromite is a magmatic mineral, which occurs in ultrabasic rocks. When the ore bearing rocks are weathered and damaged, chromite is often transferred into placers. Chromite is the main mineral raw material for smelting chromium, and low-grade ores rich in iron can be used as high-grade refractories.

Chromium rich

It is also called chromite spinel or aluminochromite. The chemical composition is Fe (Cr, Al) 2O4, containing 32% ~ 38% Cr2O3. Its morphology, physical properties, origin, occurrence and use are the same as those of chromite.

Hard chrome tip

The chemical composition is (Mg, Fe) (Cr, Al) 2O4, containing Cr2O3 32%~50%. Its morphology, physical properties, origin, occurrence and use are also the same as those of chromite.

Chrome gravity machine

Jig machine

Mining jig machine /Mineral ore separator based on the screen device,effectively improve the jig effective particle size ,coarse grain of monomer dissociation degree high mineral has good separation indexes ,widely used in manganese oxide,Chrome,hematite,limonite,iron ore,pyrite,fluorite,barite,lapis lazuli and ferrochrome smelting slag,nickel iorn slag,silicon manganese smelting slag sorting operation

Shaking table

6S Gold Shaking Table is one of the main equipments of gravity concentration applied on separating Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, Niobium , other rare metals & the noble metal ore.

Spiral chute

Spiral chute is one of the best concentrating equipment, especially for concentrating sand ore in seashore and riverside. It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; The advantages are light, moisture proof, and anti-rust,corrosive proof and no noise, properly suitable for the different feeding particle sizes and grades.

Parameter of the Chrome ore concentrate machine

Chrome ore introduction

Chromium ore is black, in granular structure and massive structure. The ore mineral is mainly chromite, and gangue mineral is olivine, pyroxene, etc. The ore grade is 40%, hardness is 4.5-5, and specific gravity is about f3.5-4.

The content of Cr2O3 in chromium minerals with industrial value is generally more than 30%, and the common ones are:

Chromite

The chemical composition is (Mg, Fe) Cr2O4, which is between ferrochromite (FeCr2O4, containing 32.09% FeO and 67.91 Cr2O3) and magnesia chromite (MgCr2O4, containing 0.96% MgO and 79.04% Cr2O3). Generally, both ferrochromite and magnesia chromite are also called chromite. Chromite is an equiaxed crystal system, with fine octahedron crystals, usually in granular and dense massive aggregates, black color, brown streaks, semi metallic luster, hardness of 5.5, specific gravity of 4.2~4.8, and weak magnetism. Chromite is a magmatic mineral, which occurs in ultrabasic rocks. When the ore bearing rocks are weathered and damaged, chromite is often transferred into placers. Chromite is the main mineral raw material for smelting chromium, and low-grade ores rich in iron can be used as high-grade refractories.

Chromium rich

It is also called chromite spinel or aluminochromite. The chemical composition is Fe (Cr, Al) 2O4, containing 32% ~ 38% Cr2O3. Its morphology, physical properties, origin, occurrence and use are the same as those of chromite.

Hard chrome tip

The chemical composition is (Mg, Fe) (Cr, Al) 2O4, containing Cr2O3 32%~50%. Its morphology, physical properties, origin, occurrence and use are also the same as those of chromite.