China spiral chute separator gold spiral wheel concentrator ore

Video of Spiral chute screw concentrate machine

Introduction of Spiral chute screw concentrate machine

Spiral chute is one of the best concentrating equipment, especially for concentrating sand ore in seashore and riverside. It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; The advantages are light, moisture proof, and anti-rust,corrosive proof and no noise, properly suitable for the different feeding particle sizes and grades.

The separator machine is a gravity spiral separating machine. The slurry produced inertia centrifugal force in rotary motion, and with gravity help in the same time, to promote light and heavy mineral zonation in the spiral chute, and continuous discharge respectively.

Application:

separate coal, iron ore, chromite, gold, pyrites, tungsten ore, tin ore, niobium ore as well as other non-ferrous metals, and nonmetallic ore with gravity difference, especially suitable for sand ore separation.

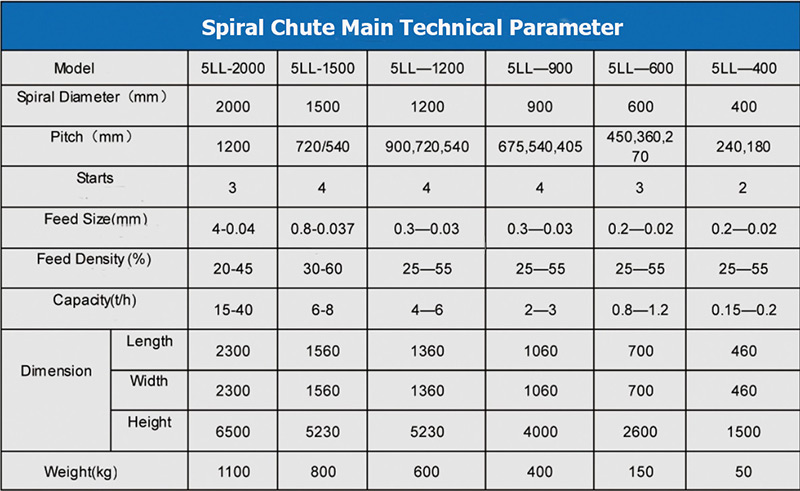

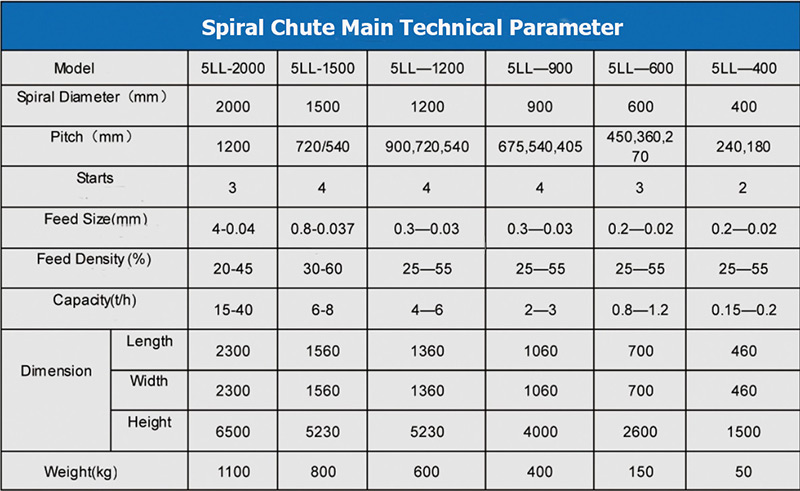

Parameter of the Spiral chute screw concentrate machine

The spiral chute has successfully replaced the original spiral concentrator at the Keketuohai Niobium and Tantalum Concentrator. It is combined with a shaking table to process primary niobium and tantalum ore less than 1 mm. The comparison index is shown in the table below. It is also effective for vanadium-titanium magnetite. Industrial tests of magnetic separation tailings (containing ilmenite) and sand tin ore have been carried out, and satisfactory results have been obtained. In the sorting test of placer tin ore, the effect is close to that of a shaking table.

Features of Spiral chute screw concentrate machine

Clear separation, High recovery, High efficiency.

Moisture proof, Antirust, Corrosion resistance, Small footprint.

Reasonable structure, Easy installation, Small occupation area.

Great processing capacity, Large handling capacity, Smooth operation.

Resilient for feeding amount and density, Granularity mineral taste, No noise.

Low operating cost, Long working life, Non-required power, small investment.

Less water consumption, simple structure, no driving force, simple to install, convenient operation.

Spiral chute screw concentrate machine operation manual

1. The main process parameters affecting spiral chute beneficiation are ore volume and ore solubility. The stability of feed volume supervision is more important than the stability of feed concentration. Practice has proved that as long as the volume of ore feeding body is constant, the fluctuation of ore feeding concentration within a certain working range has little influence on the separation results.

2. The spiral chute sorting process is stable and easy to control. The volume of ore body is 1.2-1.8 cubic meters per head per hour for LL-900 and 2.5-3.5 cubic meters per head per hour for LL-1200 The distribution characteristics of minerals along the width of spiral groove that can be changed by volume shall be controlled stably in the day, and the allowable fluctuation range shall be less than ± 5%. Generally, constant pressure ore feeding is adopted.

3. The allowable variation range of ore feeding concentration is large, generally 30%~60%, which shall be determined by test. The feed concentration of roughing can generally be 30%~50%, and that of concentration can be 40%~60%. When the separation effect is similar, it is better to select high concentration to improve the processing capacity of the equipment.

4. In order to ensure the normal operation of the FRP spiral chute, the slag separation treatment shall be strictly carried out before the slurry is fed into the spiral chute to prevent large particles and sundries from accumulating on the spiral chute surface and damaging the separation.

5. The yield and grade of each product can be changed by adjusting the position of the valve block on the product interception tank. The cutting width of each product shall be determined through experiments. Once the valve block position is determined, it shall not be changed at will.

6. After the ore is fed to the spiral chute, attention should also be paid to whether the ore flow is full of the whole spiral chute surface. If the ore flow is found to be outside, it must be corrected (such as water flushing).

7. During the operation, it is necessary to regularly check whether there is accumulation on the spiral chute, and timely clean up the accumulation found. Flush with water every shift

The groove surface shall be cleaned once to ensure the normal flow of ore flow.