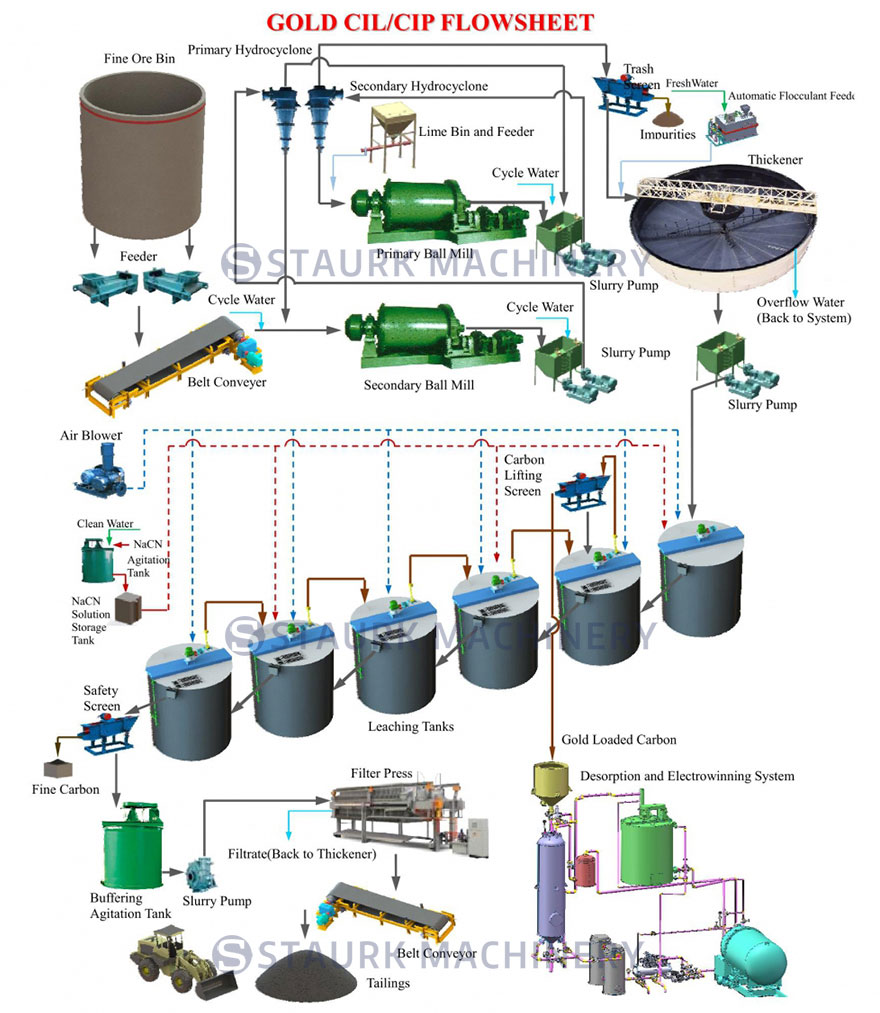

| Machine Name | Model | QTY |

|---|---|---|

| Fine Jaw Crusher | PEX150x750 | 1 |

| Vibrating Screen | SZZ900x1800 | 1 |

| Swaying Feeder | BK400x400 | 1 |

| Gold Ball Mill | MQG1500x3500 | 1 |

| Spiral Classifier | FLG1200 | 1 |

| Cyclone | FX-125-II | 2 |

| Slurry Pump | 50-ZBD-50 | 2 |

| Submerged Pump | 15-YP-25 | 1 |

| Mining Thickener | NZS-10 | 1 |

| agitation tank | BJW-1000x1000 | 1 |

| Liner Vibrating Screen | DZS0415 | 1 |

| Leaching Tank | SJ3.5x4.0 | 7 |

| Roots Fan | L42LD | 2 |

| Carbon Separation screen | SY300 | 6 |

| agitation tank | BJW-1000 | 1 |

| Air lifter | KT-100 | 1 |

| Submerged Pump | 15-YP-25 | 2 |