Cement ball mill clinker grinding station production line China staurk

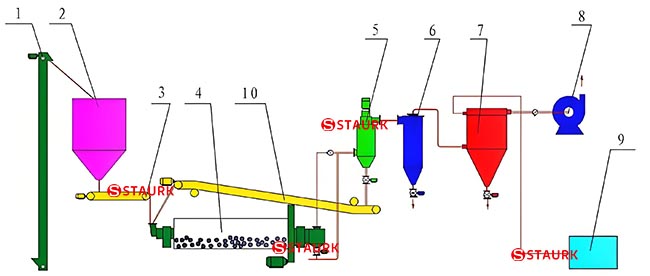

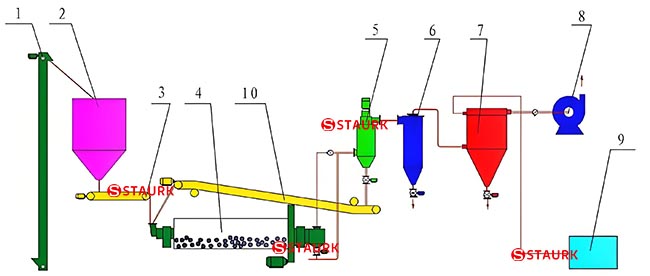

clinker grinding station production line

clinker grinding station production line including 1. Elevator 2. soil 3. Variable frequency feeding 4. Cement ball mill 5. Grading machine 6. Cyclone collector 7 Pulse dust collector 8. Induced draft fan 9. Air compressor 10. Return screw.

Cement ball mill video

Cement ball mill

Cement mill is a new generation of first stage open flow high thin tube mill. Mainly used for high-precision grinding of materials, it can be used in industries such as cement, metallurgy, chemical, refractory materials, etc.

Especially for high-precision grinding of cement to produce high-strength cement, or by adding more admixtures through high-precision grinding, the cement production can be increased while ensuring the same grade. Today, it is an ideal high-precision grinding machine.

Key features:

Not only does it have good technical and economic effects in the production of high fineness cement or other high fineness products, but it can also increase the hourly output, reduce the unit power consumption of the host and the actual power consumption of the grinder for the production of cement or other high fineness products with general fineness.

Parameter of the Cement ball mill clinker grinding

Structural composition of cement ball mill

Cement ball mill composed of transmission parts, main bearings, feeding and discharging devices, rotating parts, and other components.

1.Transmission part:

The transmission system includes an electric motor, a reducer, a transmission shaft, large and small gears, and couplings, etc.

2.Feeding device

The feeding device mainly consists of a feeding hopper, a bracket, an observation door, etc.

3.rotating part

The rotating part is composed of a material ball separation device consisting of an inlet and outlet spiral tube, an inlet and outlet hollow shaft, a large gear, a cylinder body, a lining plate, an overflow type compartment plate, an overflow type grate plate, a guide material, a lifting system, and blind plates.

4.main bearing

The main bearing is composed of main components such as spherical tiles, bearing seats, and upper covers

5.Discharge device

The discharge device is composed of discharge hood, bracket, discharge sieve and other components.

Features

1. Solved the problems of material aggregation, sticky medium, inner lining plate, compartment plate, and grate plate in high precision grinding of ordinary mills.

2. The material ball separation device is composed of overflow type compartment plate, overflow type grate plate, guide and lifting system, and blind plate.

3. Small grate plates with perforated grates are used at the outlet of the tail compartment, and special grinding materials are used for grading.

4. Based on the principle that the particle size of the material should be suitable for the size of the grinding body, a small forged steel section is used in the tail warehouse to increase the grinding area between the material and the grinding body, resulting in a significant high-precision grinding effect and good economic benefits for the mill.

5. In special circumstances, a powder selector can also be equipped to achieve finer grinding results.

Parameter of the Cement ball mill clinker grinding

Structural composition of cement ball mill

Cement ball mill composed of transmission parts, main bearings, feeding and discharging devices, rotating parts, and other components.

1.Transmission part:

The transmission system includes an electric motor, a reducer, a transmission shaft, large and small gears, and couplings, etc.

2.Feeding device

The feeding device mainly consists of a feeding hopper, a bracket, an observation door, etc.

3.rotating part

The rotating part is composed of a material ball separation device consisting of an inlet and outlet spiral tube, an inlet and outlet hollow shaft, a large gear, a cylinder body, a lining plate, an overflow type compartment plate, an overflow type grate plate, a guide material, a lifting system, and blind plates.

4.main bearing

The main bearing is composed of main components such as spherical tiles, bearing seats, and upper covers

5.Discharge device

The discharge device is composed of discharge hood, bracket, discharge sieve and other components.