Three kinds of Tin ore processing plant

1. Alluvial sand tin ore processing plant : Washing and Gravity

Alluvial sand tin ore processing plant 1

The beneficiation process of the alluvial tin ore is relatively simple. Generally, a good beneficiation index can be obtained through simple screening and gravity separation, but for the beneficiation of the alluvial tin ore with a low monomer dissociation degree, it needs to be added in addition to the screening and gravity separation. Grinding and secondary gravity separation and tailings recovery processes to ensure the grade of concentrate and the recovery rate of the entire process flow.

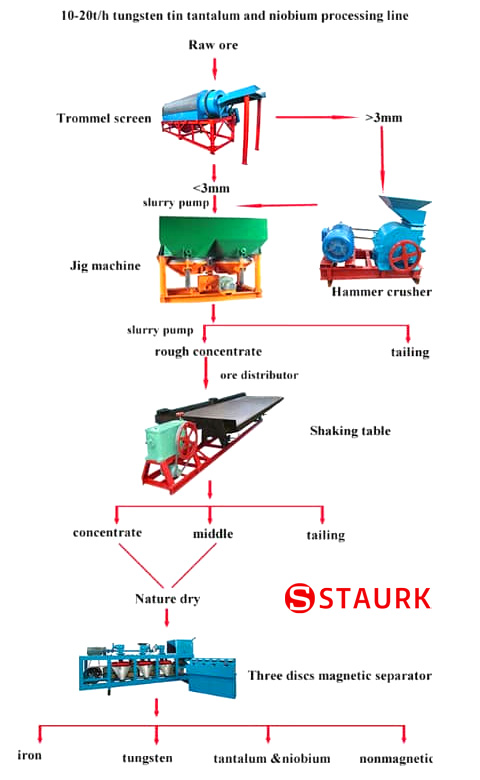

Process flow chart of sand tin ore beneficiation:

The process flow is designed according to the alluvial tin ore with low monomer dissociation degree. First, the loader is used to feed the raw alluvial into the feeding device of the trommel. After the sieving action of the trommel, the large pieces of tin-free waste are removed. The stone is thrown away, and the remaining alluvial enters the jig for sorting. The main purpose of the first stage of the jigging machine is to recover all the sand and tin minerals. It is necessary to ensure the highest gravity recovery rate rather than improving the grade of the concentrate. This section of gravity separation should use jig with large processing capacity and high recovery rate. The coarse concentrate produced by the jig enters the rod mill for grinding, breaking the tin minerals in the contiguous structure of the coarse concentrate. , The tailings are directly discarded.

2. Stone tin ore processing plant : Gravity

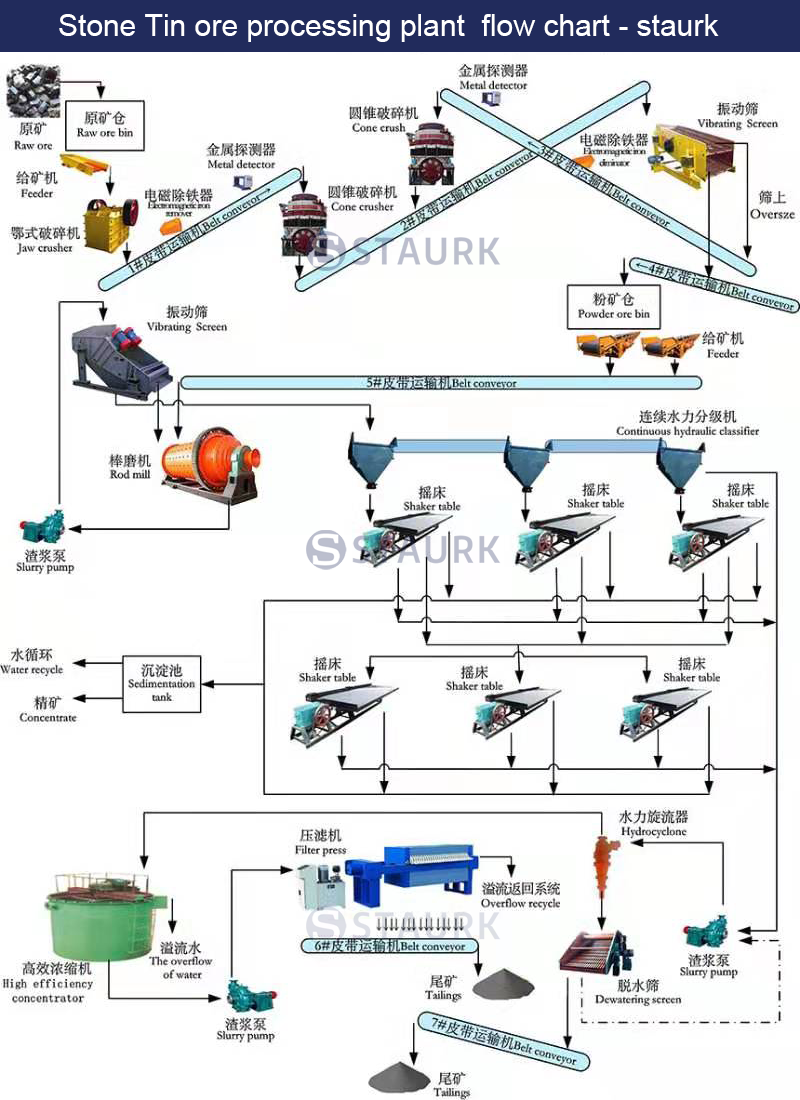

Big capacity of tin ore processing plant flow chart

Application : for stone tin mining , big capacity

Step1: crushing stage

This stage for crushing the stone tin into small parts, for rod mill,including PE jaw crusher as primary crusher , and fine jaw crusher or cone crusher as secondary crusher.

This stage can crush the tin mining into size below 25mm, the small the better.

Step2: Grinding stage

This is stage grinding the material into small powder, usually by rod mill,not ball mill , to get an even fine powder ,before next stage.

Usually this stage is most expensive with rod mill.

Step3: Sepetation stage

After rod mill, the material will be sent to shaker table to separate the tin mining, this will get what we want, and shaker table can get better tin concentrate and with low cost.

Step4: Tailings stage

The rod mill is an efficient fine crushing equipment that can grind minerals to fine sand without over-grinding, and reduce the loss of tin minerals in the gravity separation process caused by the over-grinding of tin minerals during the grinding process.

The ore products of the rod mill enter the second-stage jigging machine for secondary re-selection. The purpose of this process is to improve the grade of the concentrate. Because the rod mill has a smaller output particle size, the second-stage jigging beneficiation adopts fine-grained re-selection serrations. The wave jig machine improves the concentrate grade and guarantees the highest recovery rate.

The concentrate produced by the jigging machine can be used as the final product. The tailings enter the shaker for secondary gravity separation to recover the fine tin minerals in the jigging machine tailings. The main purpose is to improve the recovery rate of the entire process.

The concentrate from the shaking table and the concentrate from the jigger merge into the concentrate pool, and the tailings are directly discarded.

3.Gravity-Flotation plant for tin ore

Crushing and screening

The raw ore is crushed to 20mm, and then sieved into two sizes of 20~4 and 4~0mm.

Preselection

The 20-4mm ore is pre-selected in a heavy-medium cyclone, and then pre-selected by a jig after a rod mill. The jig tailings are screened out with a 2mm vibrating screen +2mm as waste tailings, and -2mm enters the shaker for sorting.

Flotation

After grind the jig and shaker concentrates separately, perform mixed flotation, and the mixed flotation tailings are shaken to produce qualified tin concentrates. The mixed flotation concentrate is finely ground for lead-zinc separation flotation, and lead-antimony concentrate and zinc concentrate are produced respectively.

Re-election

The sludge enters the Φ300mm cyclone, and the overflow is passed through the Φ125mm and Φ75mm hydrocyclones to remove the fine sludge. After the sediment is concentrated and desulfurized by flotation, the cassiterite flotation is carried out.