5) According to the function:

ordinary liner board and graded liner board.

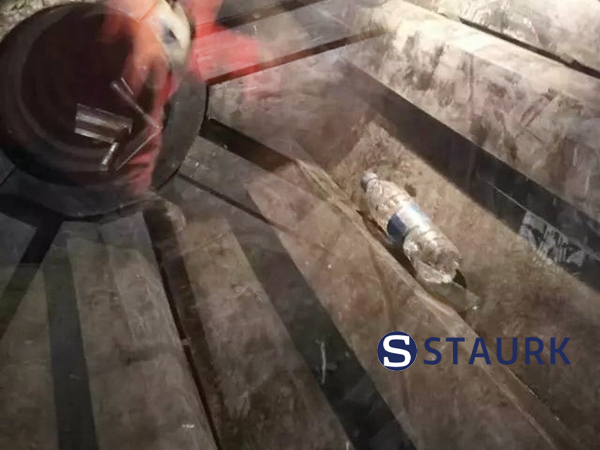

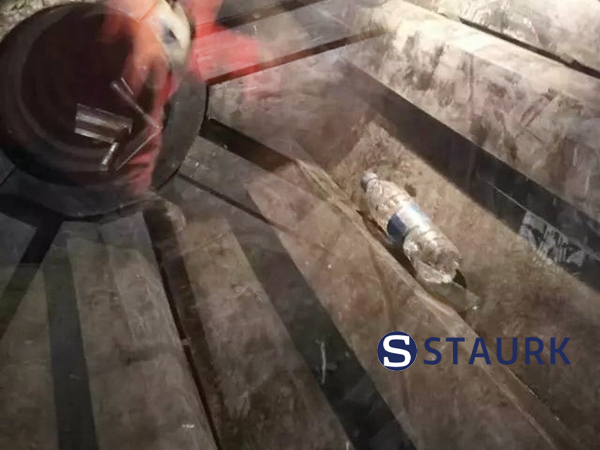

3.Installation requirements of Liner

1)The bolts of the fixed end lining plate shall not be filled with cement mortar, and shall be able to rotate or enter and exit.

2)The lining plate is generally directional, and attention must be paid during installation, not to be reversed.

3)The arc length of all the circumferential gaps should not exceed 310mm, and the places exceeding them should be wedged with steel plates to cut them off.

install liner of ball mill

4)The gap between adjacent lining plates is not more than 3~9mm.

5)A partition should be laid between the lining plate and the inner surface of the cylinder according to the design requirements. If there is no requirement, cement mortar with a compressive strength grade of 42.5MPa can be filled between the two, and the excess part can be squeezed through the strong lining plate bolts. Come out, and tighten the lining bolts again after the cement mortar solidifies.

install liner of ball mill

6)When installing a liner with a rubber backing plate, open the rolled rubber sheet 3 to 4 weeks before installation to allow it to stretch freely; when using a rubber sheet, the long side of the rubber sheet should follow the cylinder body Axial, the short side follows the circumference of the cylinder.

7)Carefully check the liner bolt holes and the geometry of the liner bolts, and carefully clean the liner bolt holes and flashes, burrs, and protrusions on the liner bolts, so that the bolts can freely penetrate to the required position.

install liner of ball mill

8) A complete set of lining bolts should be composed of dazzling bolts, dust-proof washers, flat washers, spring washers and nuts; in order to prevent dust leakage, do not forget to use dust-proof washers when in use.

9)Use a torque wrench when tightening the liner bolts. Liner bolts of different specifications should be tightened according to the corresponding tightening torque requirements.

install liner of ball mill

10)Pay attention when installing the ball mill barrel liner, the liner is generally longer than the mill barrel, the installation workers inside the mill install a row of lining plates, and the workers outside the mill must lock the nuts in time, and the mill needs to be rotated All bolts must be tightened with nuts to prevent displacement of the lining plate and the lifting bar during rotation.

4. Maintenance details of liner

Reasonable selection of ball mill liner and steel balls is one of the main ways to reduce the wear rate of the liner.

When selecting a ball mill, it is necessary to select the appropriate ball mill liner according to the type of minerals, control the hardness of the ball mill liner and the steel ball, and make a reasonable match between the steel ball and the liner.

2)The unreasonable heat treatment of the ball mill lining plate will not only increase the wear of the lining plate, but also affect the yield strength of the lining plate, resulting in the fracture of the fixing bolts of the ball mill lining plate.

Preheating the ball mill liner can effectively reduce the wear degree of the ball mill liner.

If the ball mill is running at a low load, the steel balls will directly impact the lining plate, causing serious wear and even breakage of the ball mill lining plate.

3)When the ball mill is running under a low load state, it is necessary to adjust the ore input of the ball mill in time to ensure the grindability of the material.