China Ball Clay rotary dryer, ball powder clay Slurry oven rotary dryer for sale

Condition:New

Origin:Henan, China

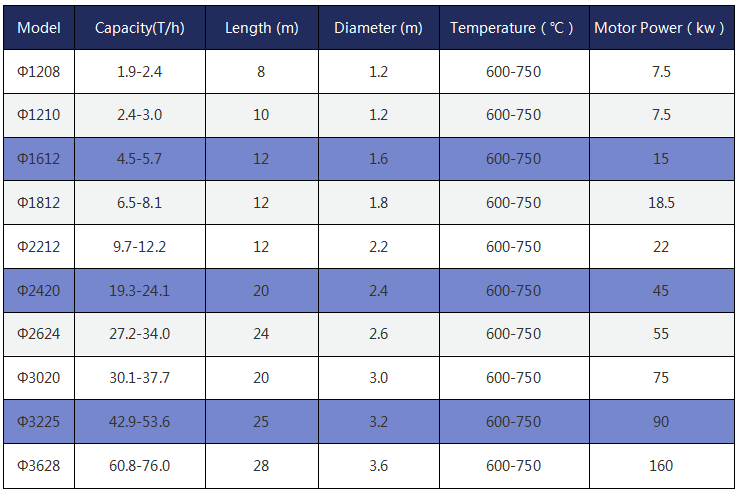

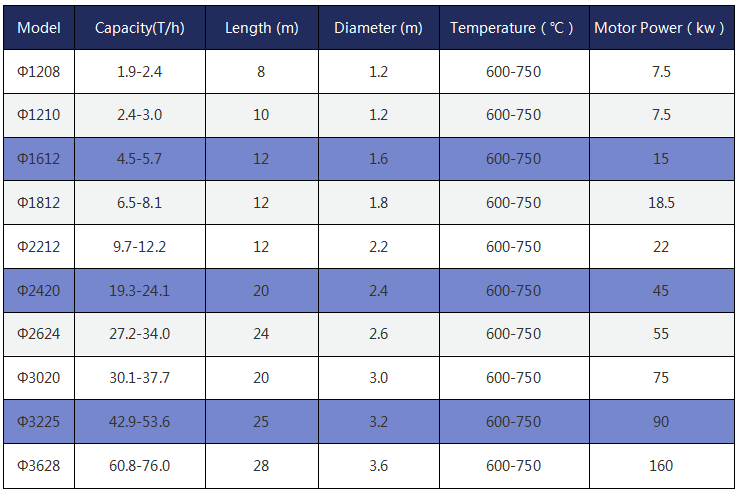

Daily Capacity:40-1520 T/D

Drying Temperature:600- 750℃

Total Installed Power:7.5-160 kw

Final Moisture:12-15% (adjustable)

Used for:Ball Clay , Ball powder, coal, mining, slime, bauxite, kaolin, bentonite, aluminum slag, metal slag, etc.

China Ball Clay rotary dryer, ball powder clay Slurry oven rotary dryer for sale

Henan Staurk Machinery Co,.Ltd, China. We are the rotary dryer manufacturer, Rotary dryer is mainly composed of heat source, feeding device, belt feeder, rotary drum, belt discharger, induced draft fan, dust collector and power distribution cabinet, etc.It can use a variety of heat sources, has the characteristics of strong adaptability, fast drying speed, small footprint, customizable models, and high cost performance.

It can be used for Ball Clay , Ball powder, coal, mining, slime, bauxite, kaolin, bentonite, aluminum slag, metal slag, etc.

Parameter of the Ball Clay rotary dryer

Ball clay introduction

The ball clay gets its name because it is pressed into a ball shape during mining. A plastic clay composed of kaolinite mixed with a certain amount of impurities such as quartz, mica and organic matter.

Sometimes it also contains a small amount of impurities such as pyrite, marcasite and siderite, so the amount of ceramic body should not be too much.

Because of its good plasticity, it is often used to improve the forming properties of blanks.

Working principle of ball clay rotary dryer

According to the principle of heat work, the drum is equipped with lifting plates and guide plates with different angles and spacings. This structure can ensure that the dried material moves along the spiral movement direction under the action of gravity, and maintains sufficient residence time in the drum And sufficient dispersion;

Cause the material in the cylinder to fully heat exchange with the hot air flow from the combustion chamber;

The defects of small heat exchange area and low evaporation intensity per unit volume caused by wind tunnels often appearing in the cross section of conventional drying equipment are eliminated.

Advantages of ball clay rotary dryer :

1.The dryer has a high degree of intelligence,a large production capacity,and continuous operation.

2.Excellent structure,speed control,stable operation,convenient operation,safe and reliable.

3.Good drying uniformity and strong adaptability;

4.High exhaust gas utilization rate of hot blast stove,energy saving and environmental protection;

5.Fewer failures,low maintenance costs,and low power consumption.