Manganese ore rotary dryer China polianite mine drying machine

Condition:New,for sale

Origin:China Manganese ore rotary dryer

Daily Capacity:20-1520 T/D per set

Drying Temperature:600- 1250℃ (adjustable)

Final Moisture:10-15% (adjustable)

Used for:Drying manganese ore,Rhodoarsen,akatoreite,bannisteri,hollandite,hausmannit,loseyite,ferrian,natrophili

Manganese ore rotary dryer China polianite mine drying machine

Henan Staurk Machinery Co,.Ltd, China. We are the rotary dryer manufacturer, Rotary dryer is mainly composed of heat source, feeding device, belt feeder, rotary drum, belt discharger, induced draft fan, dust collector and power distribution cabinet, etc.It can use a variety of heat sources, has the characteristics of strong adaptability, fast drying speed, small footprint, customizable models, and high cost performance.

Application - Manganese ore rotary dryer

It can be used for drying manganese ore,Rhodoarsen,akatoreite,bannisteri,hollandite,hausmannit,loseyite,ferrian,natrophili, and iron ore, cobalt ore, copper ore, gold ore, lead ore, tin ore, etc,can rapid drying their moisture.

Working principle - Manganese ore rotary dryer

When the manganese ore dryer is working, the manganese ore material is first transported to the rotating drum through the feeder and the conveyor. As the drum rotates, the manganese ore material is continuously thrown up and scattered in the drum, making full contact with the hot air, thereby obtaining evenly dried manganese ore material.

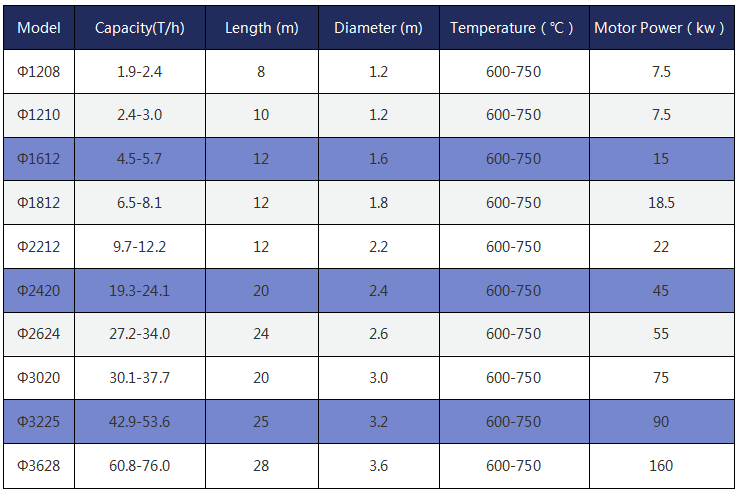

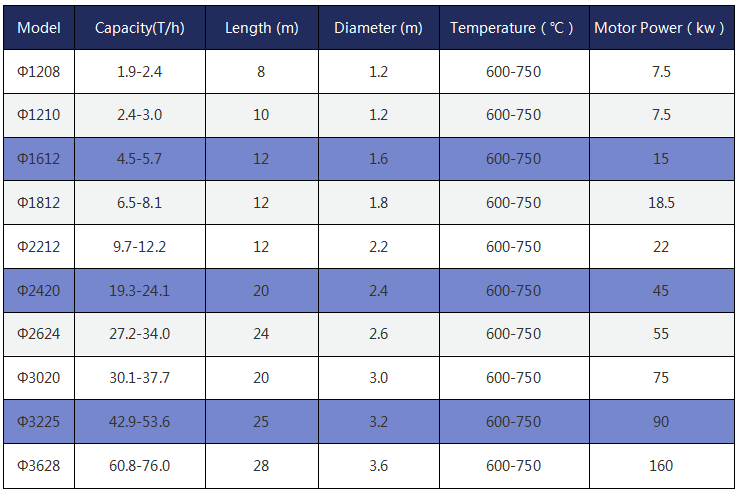

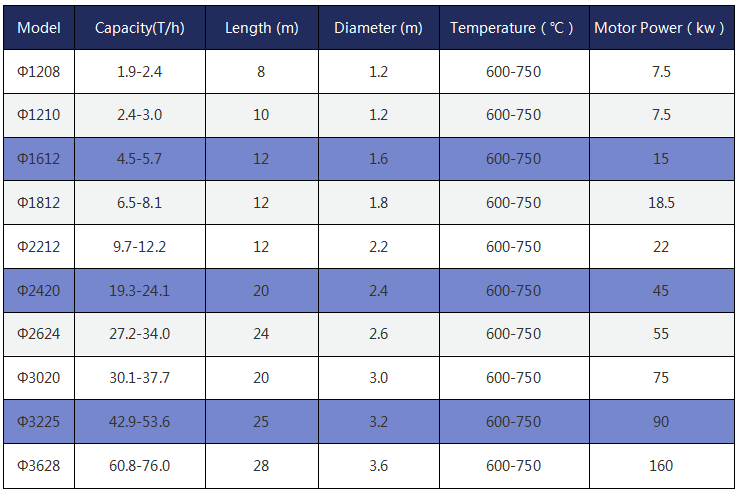

Parameter of the Manganese ore rotary dryer

Advantages - Manganese ore rotary dryer

1.The drying strength is high.Because the material is highly dispersed in the air flow,the entire surface area of the particles is the effective area for drying.

2.Short drying time

3.The airflow dryer has a simple structure,a small footprint,and is easy to construct and maintain.

4.Large processing capacity and high thermal efficiency.When drying unbound water,the thermal efficiency can reach 60%.

5.The dryer achieves"zero horizontal thrust",which greatly reduces the wear of the retaining wheel,and the cylinder runs smoothly and reliably;

6.The dryer adopts the"adjustable supporting roller device",so that the matching of the supporting roller and the rolling ring is always in linear contact,thereby greatly reducing wear and power loss;