How to add load steel balls of ball mill ? Reduce wear damage

2021-06-09

Staurk Machinery

Grinding balls for ball mill, mainly includes High, medium , low chromium alloy steel balls and High, medium , low aluminum ceramic balls.etc.The diameter of the steel balls is has 110mm, 100mm , 80mm , 60mm , 40mm , 20mm etc.Here is the steps : add load steel balls of ball mill , Reduce wear damage of balls.

1)mix large and small balls.

1)mix large and small balls.

When the ball mill is initially loaded, it must be ensured that the type of steel ball, the diameter of the ball and their weight ratio are suitable for the nature of the material to be ground.

The test results show that the general coarse mineral material should use large steel balls, and small steel balls are used to wash mineral materials. Under normal circumstances, the feed size will be different in thickness, therefore, it is necessary to mix large and small balls.

Why 80%, and not 100%. AS after the ball mill is installed, the large and small gears of the ball mill need to be meshed, and the processing capacity must be gradually increased. After the ball mill runs normally for two or three days, check the meshing of the large and small gears. When everything is normal, open the ball mill manhole cover and add the remaining 20% steel ball.

For example, MQG1500×3000 ball mill, its larger ball loading capacity is 9.5~10t, the initial ball loading should be 7.5~8t, the remaining steel balls of steel forging will be added after the ball mill is driven for 3~4 days; the weight ratio of the ball loading is Φ100 mm Accounted for 40%, Φ80 mm accounted for 30%, Φ60 mm accounted for 15%, and Φ40mm accounted for 15%.

delivery of balls for ball mill

3)Basic principles of ball mill steel balls

3)Basic principles of ball mill steel balls

Reduce the feed size as much as possible, which not only reduces the wear of steel balls, but also saves energy.

Related articles:

How to install protect steel rubber liner of ball mill ?

China mining ore grinding Ball mill manufacturer

9 ways tell you how to improve ball mill efficiency

Ball mill operate manual: what to do if has problems not working

balls for ball mill

When the ball mill is initially loaded, it must be ensured that the type of steel ball, the diameter of the ball and their weight ratio are suitable for the nature of the material to be ground.

The test results show that the general coarse mineral material should use large steel balls, and small steel balls are used to wash mineral materials. Under normal circumstances, the feed size will be different in thickness, therefore, it is necessary to mix large and small balls.

delivery of balls for ball mill

2) For the first time, add 80% of the ball mill's maximum ball load.

Why 80%, and not 100%. AS after the ball mill is installed, the large and small gears of the ball mill need to be meshed, and the processing capacity must be gradually increased. After the ball mill runs normally for two or three days, check the meshing of the large and small gears. When everything is normal, open the ball mill manhole cover and add the remaining 20% steel ball.

For example, MQG1500×3000 ball mill, its larger ball loading capacity is 9.5~10t, the initial ball loading should be 7.5~8t, the remaining steel balls of steel forging will be added after the ball mill is driven for 3~4 days; the weight ratio of the ball loading is Φ100 mm Accounted for 40%, Φ80 mm accounted for 30%, Φ60 mm accounted for 15%, and Φ40mm accounted for 15%.

delivery of balls for ball mill

a. When dealing with ore with large hardness and coarse particle size, it needs to have a large impact force, and it needs to load a steel ball with a larger size, that is, the harder the material, the larger the diameter of the steel ball;

b. The diameter of the mill is large, the impact force is large, and the diameter of the steel ball is small;

c. When using double-silo partitions, the ball diameter should be smaller than that of the single-layer partitions with the same discharge section;

d. Generally, four-level balls are allocated. There are few large and small balls, and the middle ball is large, that is, "two ends are less, and the middle is more".

4)No need to add too small balls

The reasonable friction between steel balls and steel balls, steel balls and ore, steel balls and ball mill liner during normal operation of the ball mill will increase the wear and tear, making large balls small and medium balls milled. for the ball. Therefore, under normal circumstances, there is no need to add a small ball.

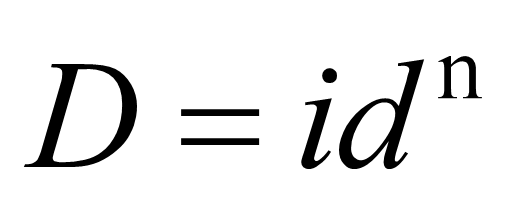

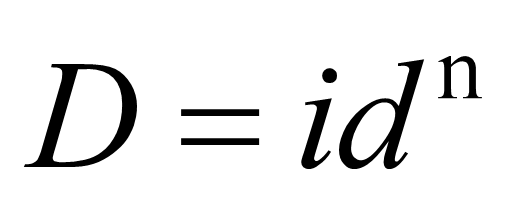

5)Calculation formula:

4)No need to add too small balls

The reasonable friction between steel balls and steel balls, steel balls and ore, steel balls and ball mill liner during normal operation of the ball mill will increase the wear and tear, making large balls small and medium balls milled. for the ball. Therefore, under normal circumstances, there is no need to add a small ball.

In the formula, D——the diameter of the steel ball, mm;

d——feed size, mm;

i and n-parameters related to the properties of mineral materials.

4)How to reduce wear damage:

The calculation of the ball loading method can generally be carried out according to the following steps.

Step 1: Determine the returned sand ratio of the classifier, screen and analyze the new ore and returned sand of the ball mill, and calculate the particle size composition of the full ore of the ball mill, which is used as the original data for calculating the diameter of the steel ball;

Step 2: From the particle size composition of the full feed, deduct the particle size that does not need to be ground again, and then convert the remaining particle size to a new percentage. Then divide the newly converted percentages into several groups appropriately. In each group, find out the steel ball diameters that should be used according to the formula and Table 1, and determine the proportions of various balls. The weight percentages of balls of various diameters are roughly equivalent to the percentages of ore particles in each group on which they are calculated;

Step 3: Calculate the loading weight of various balls according to the ratio of various balls and the total weight of the balls that should be loaded.

Reduce the feed size as much as possible, which not only reduces the wear of steel balls, but also saves energy.

Related articles:

How to install protect steel rubber liner of ball mill ?

China mining ore grinding Ball mill manufacturer

9 ways tell you how to improve ball mill efficiency

Ball mill operate manual: what to do if has problems not working