Gravity beneficiation process methord for placer alluvial gold ore

2021-05-06

Staurk Machinery

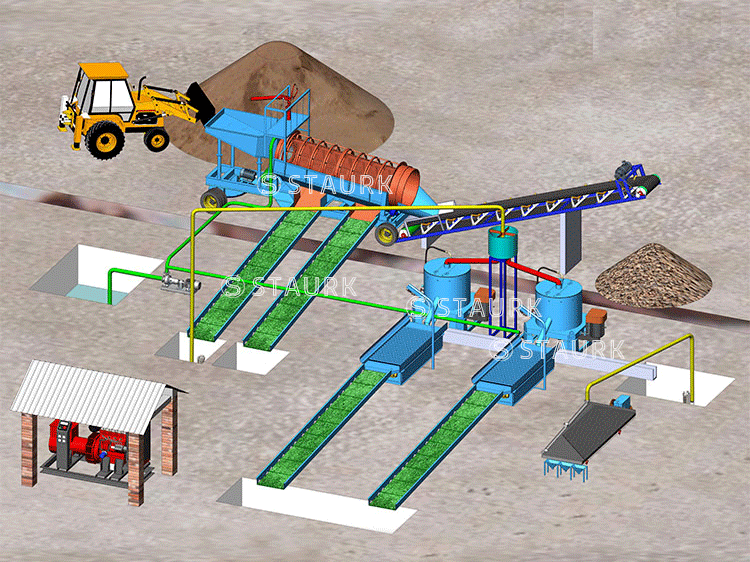

one of commen plant for alluvial gold ore

Gravity beneficiation is a process that takes advantage of the difference in density and particle size of minerals, and uses the combined action of medium fluid and various mechanical forces to create suitable loose layering and separation conditions, so as to obtain products of different densities or different particle sizes.

Since most gold-bearing ores contain a certain amount of coarse-grained free gold (+0.1mm), it is difficult to recover by flotation and hydrometallurgy.

Therefore, the gravity beneficiation method is mostly used to separate placer gold and vein gold to recover coarse-grained gold from monomer dissociation before and after floatation and leaching.

Generally, the lower limit of the particle size of gold that can be recovered by the gravity separation method is 0.01 mm.

The gravity separation process is mainly used for the separation of placer gold ore. One is because the specific gravity and coarse particle size of placer gold are generally 0.074~2mm, and the other is because the gravity separation process is economical and simple. Gravity separation is a key operation in the beneficiation stage of placer gold mines. Gravity separation equipment such as Centrifugal concentrator, Trommel, jigs, shaking table, and chutes are often used to discharge most of the waste rock to obtain crude gold concentrate.

Since most gold-bearing ores contain a certain amount of coarse-grained free gold (+0.1mm), it is difficult to recover by flotation and hydrometallurgy.

Therefore, the gravity beneficiation method is mostly used to separate placer gold and vein gold to recover coarse-grained gold from monomer dissociation before and after floatation and leaching.

Generally, the lower limit of the particle size of gold that can be recovered by the gravity separation method is 0.01 mm.

The gravity separation process is mainly used for the separation of placer gold ore. One is because the specific gravity and coarse particle size of placer gold are generally 0.074~2mm, and the other is because the gravity separation process is economical and simple. Gravity separation is a key operation in the beneficiation stage of placer gold mines. Gravity separation equipment such as Centrifugal concentrator, Trommel, jigs, shaking table, and chutes are often used to discharge most of the waste rock to obtain crude gold concentrate.

The jig machine can separate the placer gold under the premise that the specific gravity difference is ≥1.25 and the ore monomer is dissociated, the lower limit particle size can reach 0.04mm, the process operation is simple, the equipment processing capacity is large, and the application effect is very good in the rough gold mine.

Shaking table gold beneficiation is suitable for processing minerals with finer particle size. The gold beneficiation is stable and reliable, and the distribution of ore belts is clearly visible. The rich ore is higher than other beneficiation methods, easy to manage, and can be used to separate the required ores at one time. According to the different particle size of the ore, the shaking table can be divided into three types: coarse sand bed, fine sand bed and ore mud bed:

◆ Coarse sand bed is suitable for sorting ore particles with a material size between 0.5-2.0mm;

◆ The fine sand bed is suitable for processing ore particles with a material size range of 0.074-0.5mm;

◆ The sludge bed is suitable for processing ore particles with a material size of 0.037-0.074mm.