Tyre ball mill, tire drive rubber liner low-noise - China staurk

What is a tyre ball mill ?

Tyre ball mill are mainly suitable for dry and wet grinding solutions in the electric power and mining industries; due to the tire-driven method, the inner liner of the ball mill is generally made of rubber liner with light weight, low noise and high wear resistance. And sometimes manganese steel liner is also ok . The grinding medium can be

steel balls, ceramic grinding balls, steel rods or stone balls, etc.

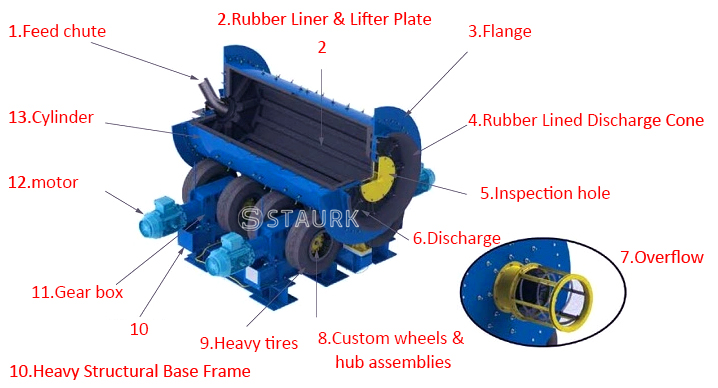

Tire ball mill structure

Tire ball mill consists of Feed chute,Rubber Liner and Lifter Plate Assemblies,Flange,Rubber Lined Discharge Cone,inspection hole,discharge port,Overflow,Custom wheels and hub assemblies,heavy tires,Heavy Structural Base Frame,Helical Gearbox,motor,and Cylinder etc

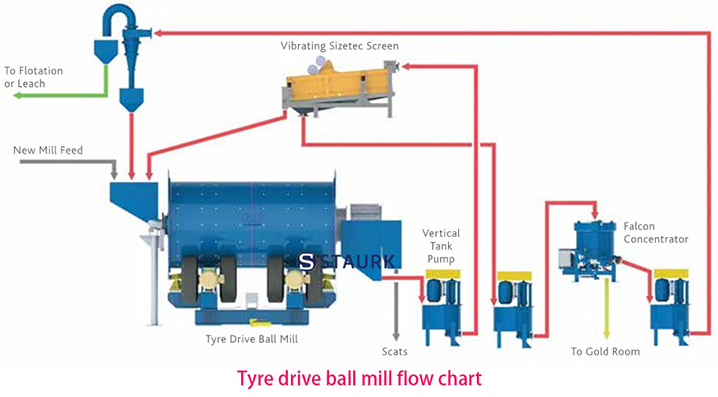

Tire ball mill flow chart

Just take as a reference

Just take as a reference

The difference between tyre ball mill with ordinary ball mill

1. Transmission method

Tire ball mills usually use tires as transmission

Ordinary ball mills use gear drive, ceramic ball mills mostly use belt drive

2. Liner

Tire ball mills usually use rubber liner, but can also use high manganese steel liner,

Ordinary ball mill usually use

manganese steel liner, polyurethane linings, ceramic liner and other materials

Application of tire ball mill

The tire ball mill is mainly suitable for dry and wet grinding solutions in the power and mining industries. More than 300 kinds of materials such as iron ore, gold ore, copper ore, zinc ore, quartz sand, tungsten carbide and lime etc.

Parameter of the Tyre ball mill

|

Model |

Diameter(mm) |

Length(mm) |

Speed(r/min) |

Capacity(t/h) |

Power(kw) |

Weight(t) |

|

MX2295 |

2200 |

9500 |

21.4 |

14-15 |

475 |

68.2 |

|

MX22110 |

2200 |

11000 |

21.4 |

15.1-16.1 |

570 |

85.6 |

|

MX24110 |

2400 |

11000 |

21.68 |

20.6-22.7 |

630 |

108 |

|

MX24130 |

2400 |

13000 |

19.4 |

21.6-23.8 |

800 |

121 |

|

MX26130 |

2600 |

13000 |

19.7 |

24.6-27.1 |

1000 |

169.8 |

|

MX3090 |

3000 |

9000 |

18.7 |

26.6-28.5 |

1000 |

161 |

|

MX30110 |

3000 |

11000 |

18.7 |

28.6-32.8 |

1250 |

183.5 |

|

MX30130 |

3000 |

13000 |

18.7 |

33-36 |

1250 |

199.5 |

|

MX32120 |

3200 |

12000 |

17.8 |

31.8-38.2 |

1400 |

213 |

Features of Tyre ball mill

1. Simple structure, no castings, large ring gear, bearings and lubrication system, greatly reducing maintenance costs

2. Short delivery time, low installation cost, and minimize the use of concrete required

3. Using steel structure base, strong and durable

4. No ring gears, reduction gears, drums or bearings

5. Off-the-shelf standard components, easy to replace and reduce downtime

6. Wear-resistant truck tires can be easily purchased locally

7. The discharge method can be customized (overflow discharge or grid discharge)

8. Each section has quality inspection and testing, and the test run before leaving the factory

9. Rubber lifting plate, long life and easy to replace

10. Easy to repair and maintain