Soil stone separator, 4 types mud gravel soil sieve screen machine - China

For different application , we have different separator screen machine , we will introduce one by one

Type 1: Soil separator, soil screen trommel

Type 2: Roller soil stone screen machine

Type 3: Farm soil stone separator machine

Type 4: Log washer

Type 1: Soil separator, soil screen trommel

Type 2: Roller soil stone screen machine

Portable mobile soil stone separator roller screen

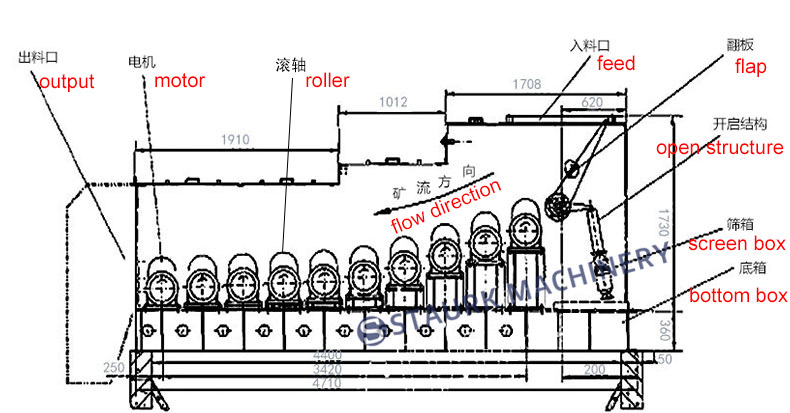

Structure of the machine:

Roller screen separator is composed of frame, bottom box, screen box, opening structure, flap, motor, reducer, roller, disc and so on.

Description:

Roller screen separator ,also called soil rock stone separator, roller screen or roller separator. A machine that can remove the soil on the surface of solid materials (stones, minerals, coal, etc.) without water.

By adjusting the rotation of the rollers and the gap between the rollers, the materials can be effectively screened.

In terms of technology, the roller screen separator is generally located at the front end of the process, and is suitable for separating a large amount of soil contained in the material, and the processed bulk material enters the next process.

Screen 3 kinds of material:

Equipped with 2 sets of rollers with different pitches to separate the mixture into three types:

1. Mud or muck,

2. Smaller block materials, such as stones and broken bricks

3. Bulk materials, such as large stones, concrete blocks, etc.

Screen 2 kinds of material:

It only needs to be equipped with a set of rollers, and it can be sieved out by adjusting the distance between the rollers.

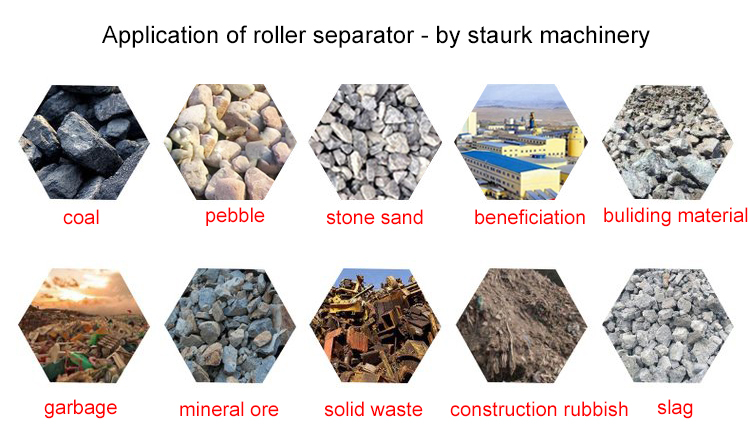

Application:

It is used to screen and separate debris, stone sand, ore, coal, coal gangue, building materials, construction waste, solid waste and other materials.

And for ore, with water, we suggest the Log washer for washing ore stone

Working principle:

The roller is installed on the frame tilted, and the motor drives the roller to rotate through the reducer and coupling; when the material enter, due to the tilt and rotation of the roller, the material on the screen surface is constantly turned and rolled, passing through the screen. separate them.

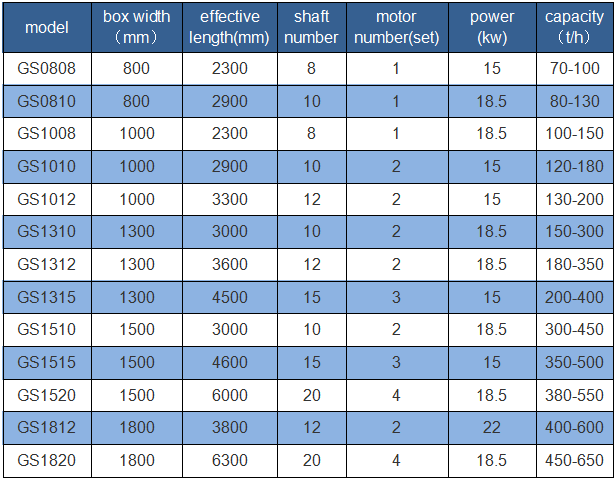

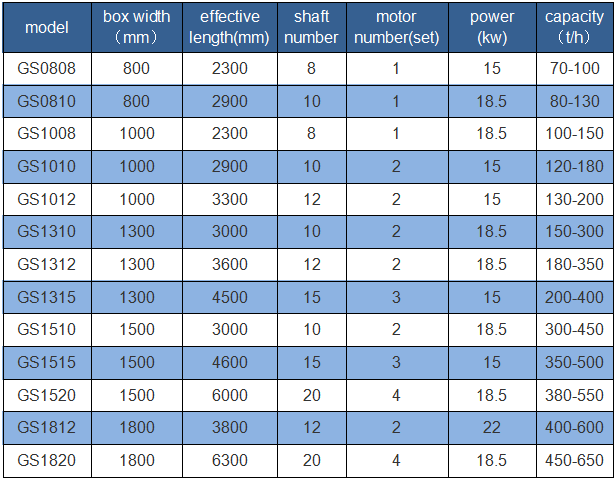

Parameter of the Soil stone screen separator

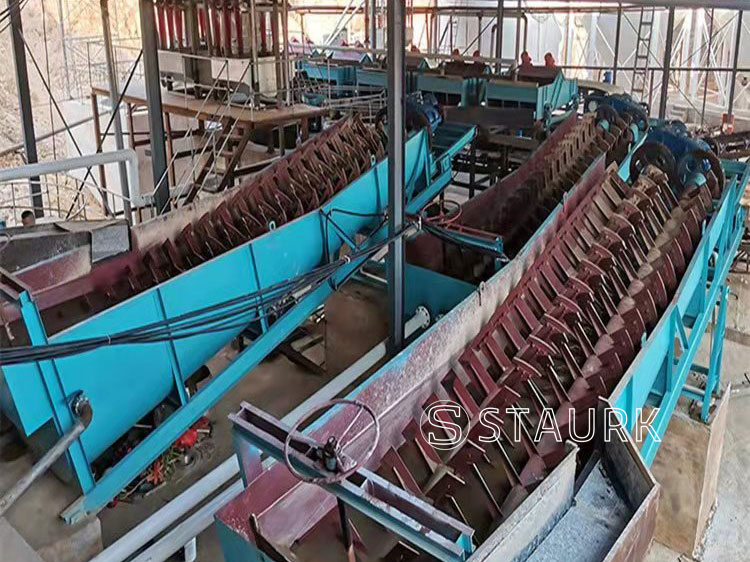

Soil stone separator roller screen for sale

Soil stone separator roller screen for sale

Soil stone separator roller screen for sale

Soil stone separator roller screen for sale

Advantage:

1. High-manganese steel liner is used in the cabinet, which is durable and easy to replace, which greatly extends the service life of the whole machine

2. The screen shaft is equipped with mechanical and electrical 2-level overload protection and anti-blocking devices.

3. Convenient inspection and repair of the screen shaft, no need to open the cover, no need to disassemble other screen shafts, it can be extracted from the side for maintenance, saving maintenance space and workload.

4. The operation is simple and flexible, and it can be controlled manually or remotely (the electric control cabinet has a program control interface)

5. The cutter head is made of alloy casting, with good wear resistance and long service life.

6.All filling points are clearly marked.

Installation Precautions:

1. Due to the large torsion of the equipment, the equipment is installed on a concrete frame with embedded welding parts. The total weight of the frame is approximately three times the total weight of the equipment.

2. After installation, check whether the reducer, large and small transmission gears are shifted, and whether the distance between the side plate of the box body and the large wheel is consistent, and after adjustment, it is fixed and welded to the frame.

3. Industrial lubricating oil should be added to adjust the height of the oil level, usually 50% below the middle of the shaft is appropriate.

Precautions for test machine:

1) Continuous operation for 2 hours:

2) All solid parts should be stable without loosening problems;

3) There is no abnormal noise from the geared motor and gear box.

5. In addition to the requirements for no-load test runs, the following requirements should also be met:

1) When feeding, the materials should not be violently impacted, and the materials should not be eccentrically loaded.

2) Pay attention to the particle sie and speed of the feed.

Type 3: Farm soil stone separator machine

Working video

Details of the machine

Type 4: Log washer