China sand washing plant machine sea river silica sand process

Sand washing plant process machine video

1.The video show 4 sand washing machine plant :

video 2: Spiral sand washing machine + dewatering screen

video 3: Wheel sand washing machine + Spiral sand washing machine + dewatering screen

video 4: Wheel sand washing machine + fine sand recycling system pant machine

For more plant machine suggestion ,please contact us.

2.Classification of Sand washing plant process machine

Sand washing machines can be divided into: wheel bucket sand washing machine, spiral sand washing machine, and fine sand recovery recycling machine , which are often used together with dewatering screens.

And in artificial sand production line,It is used together with sand making machine and stone crusher.

3.Application of sand washing plant machine:

It is suitable for washing fine-grained and coarse-grained sand.Especially construction sand and road construction sand.

Widely used for washing materials in sand and gravel fields, mining, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing stations and other industries.

Especially used in construction sites, sand and gravel plants, hydropower stations, concrete dam sites, foundry sand, quartz sand in glass factories and pressure sand for oil well backfilling, etc.

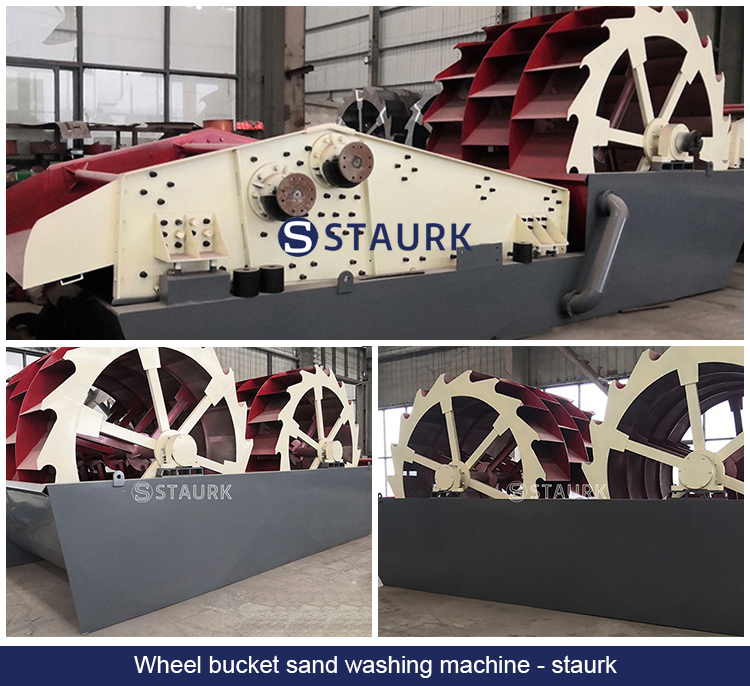

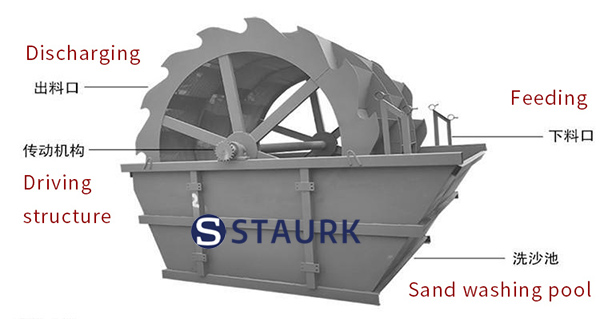

China Wheel bucket sand washing machine

4.Wheel bucket sand washing machine

It can wash the mixed sand produced by the sand making machine to remove trace amounts of stone powder and impurities, thereby improving the quality of the sand.

Mainly used for washing, grading and dehydration of quartz sand in sand and gravel factories, construction sites and glass factories.

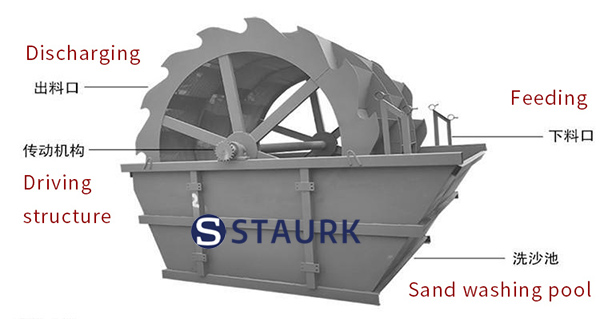

Wheel sand washing machine structure

The machine is driven by the motor and reducer to drive the impeller in the water tank to rotate continuously in the water tank, so as to stir, turn over, and wash the water-receiving material in the water tank. It is discharged after dehydration in the impeller.

China screw sand washing machine

5.Screw sand washing machine

Spiral screw sand washing machine is divided into two types: single-screw sand washer and double-screw sand washer, which are mainly used for washing, grading, impurity removal, fine-grained and coarse-grained material washing in highway, hydropower, construction and other industries. .

It has low power consumption and high cleaning degree. Good sealing structure, fully enclosed transmission device and adjustable weir plate ensure high efficiency, durability, good cleaning and dehydration effect, and stable fine-grained products.

working principle of Spiral sand washing machine

working principle of Spiral sand washing machine

It consists of a trough body, a reducer, a motor, a central shaft, a spiral blade and a bracket. The bracket is welded on the central shaft, and the spiral blade is secured and then pressed with bolts to deform the blade without the lower body.

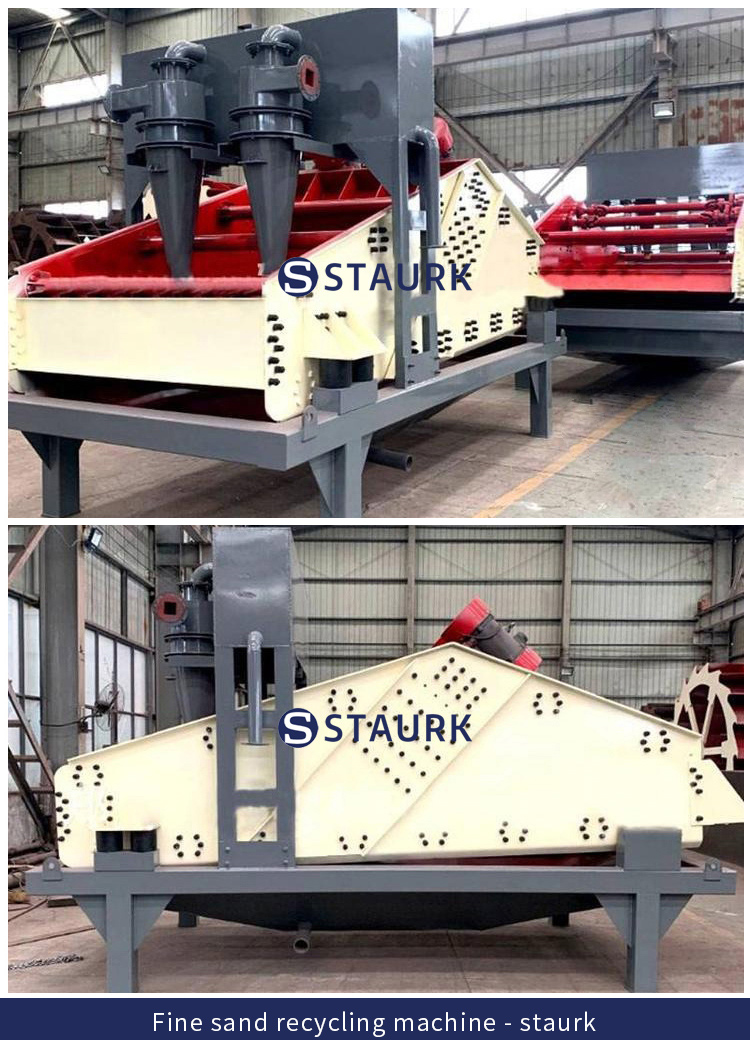

China Fine sand recycling machine

6.Fine sand recovery recycling machine

The fine sand recovery recycling machine is a device developed for dehydration, deintermediation and desliming of slurry materials.The fine sand recovery machine is also called tail sand recovery machine, fine sand extraction machine, fine sand collector, sediment separator, mud separator, sand water mixture treatment system, etc.

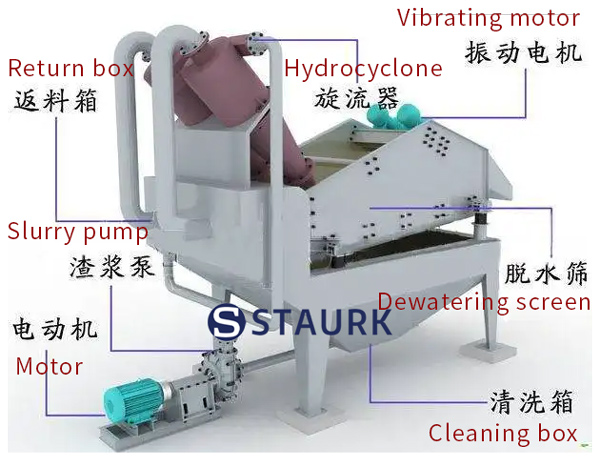

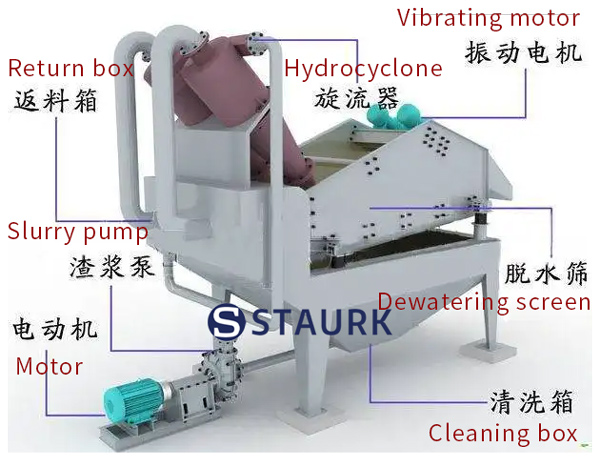

China Fine sand recycling machine structure

The fine sand recycling machine consists of a washing tank, a mortar pump, a motor, a cyclone, a linear vibrating screen, a return box, etc.

Parameter of the Sand washing plant process machine

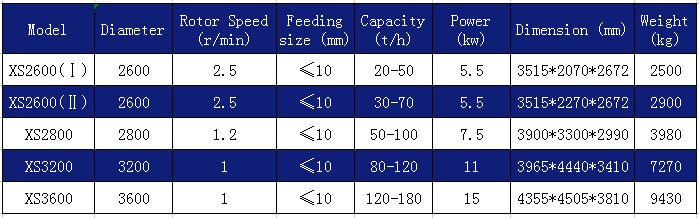

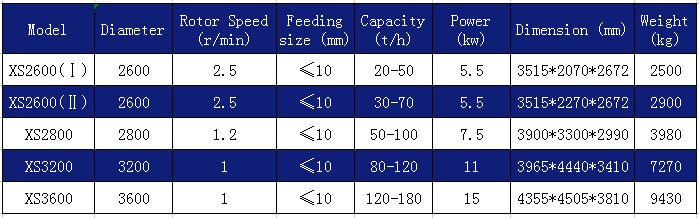

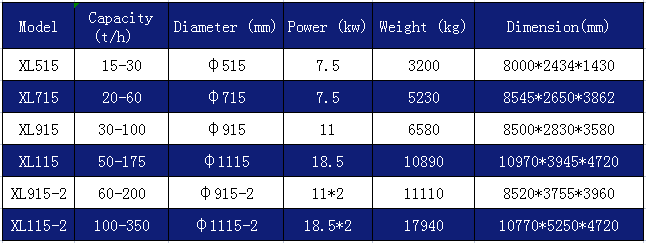

7.1 Parameter of wheel sand washing machine

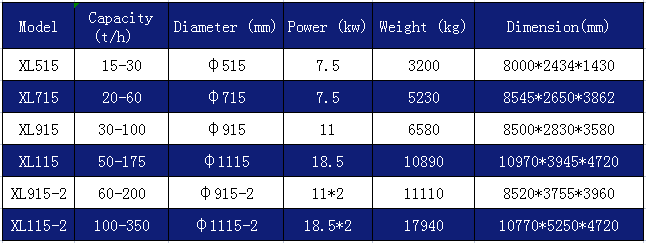

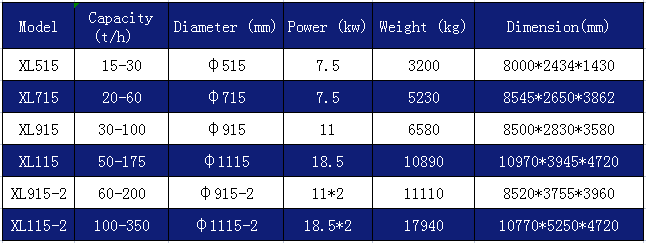

7.2 Parameter of screw sand washing machine

7.2 Parameter of screw sand washing machine

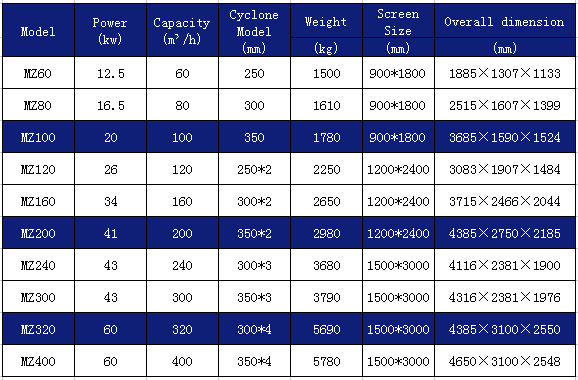

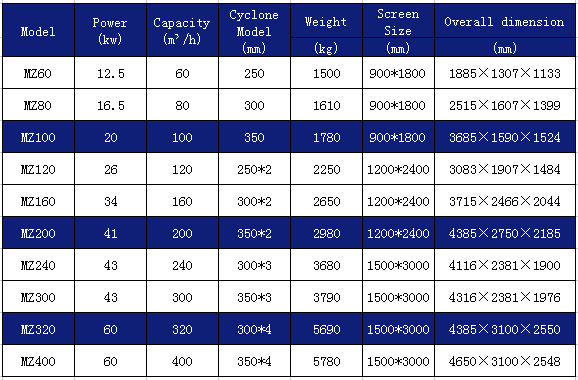

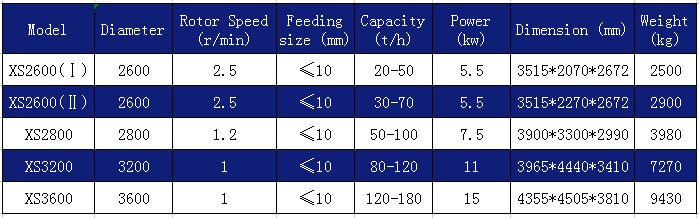

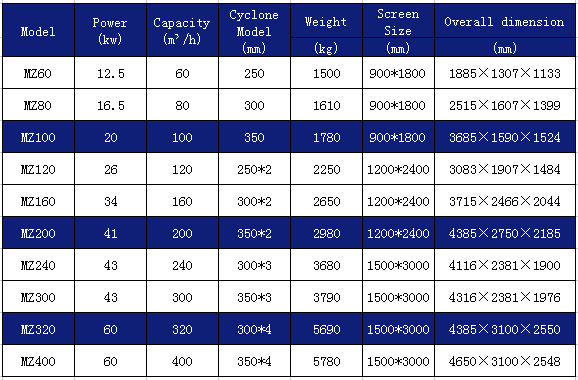

7.3 Parameter of fine sand recycling machine

7.3 Parameter of fine sand recycling machine

8.Why do you need to clean the sand ?

1. The purity is not high and does not meet the standards of construction sand

2. If the sand contains impurities, during the storage process, the sand particles will coagulate together, which will affect the normal use of the sand

3. After cleaning with a sand washing machine, the water vapor layer on the surface of the sand can be destroyed, and the water can be removed as soon as possible to achieve the cleaning effect required for construction

9.The difference between wheel sand washer and spiral sand washer

1. Sand loss rate

The wheel sand washing machine consumes less water in the sand washing process, the loss of fine sand and stone powder is very small, and the sand grade and fineness modulus of the washed construction sand can meet the standard requirements.

The spiral sand washer filters out some of the fine sand during the cleaning process, so the washed sand will be extra clean.

2. From the cleaning ability

The cleaning ability of spiral sand washing machine is better than that of wheel sand washing machine, which can effectively clean sand with serious mud impurities. It is usually configured in large-scale sand production lines.

The capacity of wheel sand washing equipment is usually less than 80 tons, so it is suitable for small and medium-sized sand production line systems.

10. Features of sand washing machine

1. Simple structure and stable operation.

2. The bearing is separated from water and materials to avoid premature damage caused by pollution and rust of the machine.

3. Suitable for a variety of working environments.

4. Less loss of washed materials and high selection and washing efficiency, which can fully meet the requirements of high-grade materials.

5. The service life is relatively long, and there are almost no wearing parts.

11.Features of Fine sand reycling machine

1. With this sand recovery, it can effectively reduce the amount of sand loss and its control in the 5 to 10%. Solves the finished sand fineness high modulus, low powder content of artificial aggregate processing system problems arise.

2. Vibrating sieve adopt polyurethane screen which is of longer life and less clogging.

3. Polyurethane lined cyclone improve the life of the entire apparatus can be successfully completed slurry concentration and liquid clarification work.

4. The sand recovery system can recycle 85% of fine particulate material, which has unparalleled technical and economic advantages than other equipment.

5. Fine particles are fully recovered, reducing the workload of the sedimentation tank, reducing the costs of cleaning up the sedimentation tank;

6. Fine sand recovery system reduces the fine material natural pile time, direct transport, supply market.

7. We can design appropriate solutions sand recovery system according to different user requirements

8. The sand recovered after dehydration can be directly stacked or combined with other finished sand pile.